- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

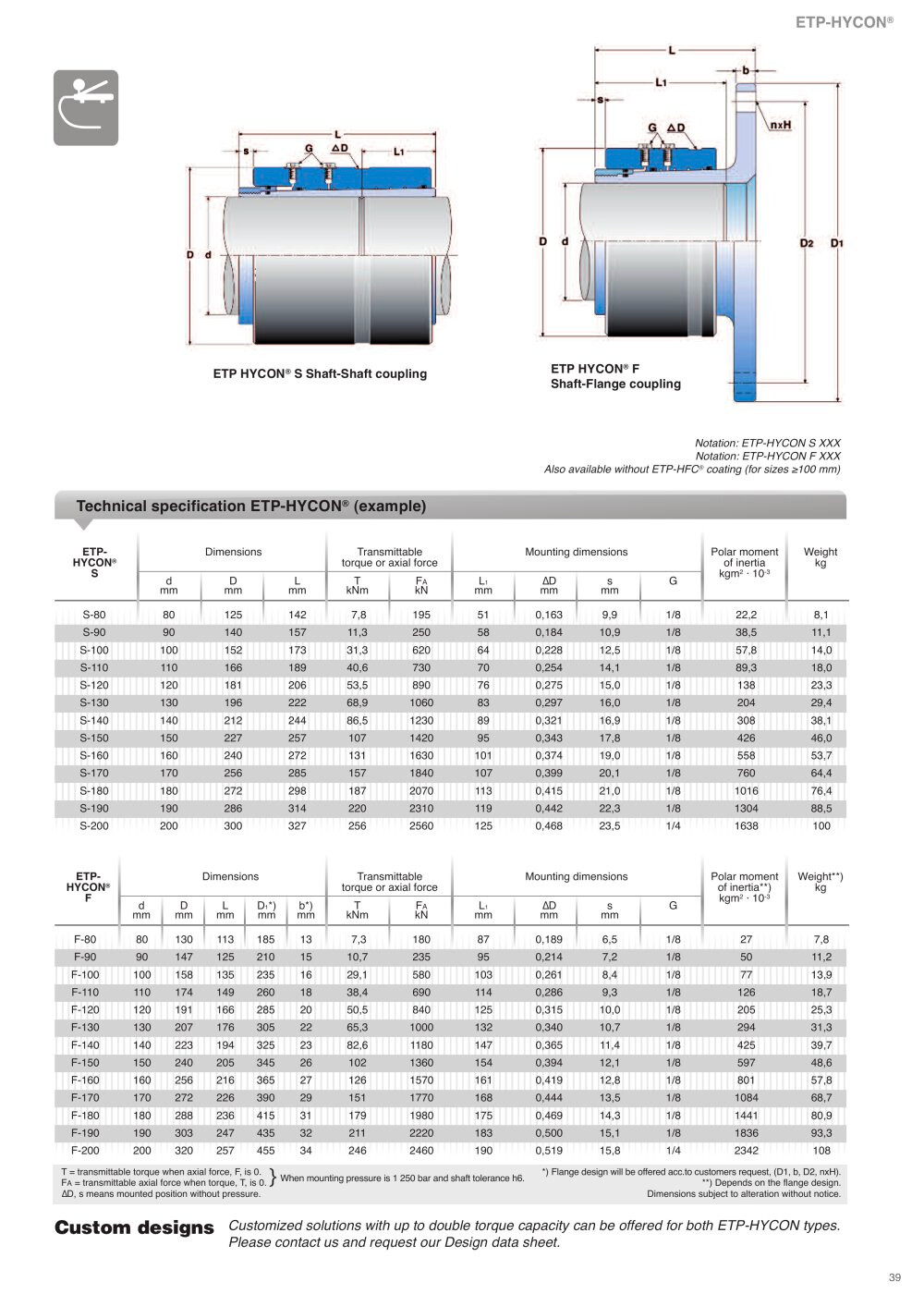

ETP-HYCON

ETP-HYCON builds on the same principle as another well-proven product in the range, ETP-HYLOC, where mounting is done hydraulically. When the coupling is mounted, a rigid joint is created, it can transmit high torque and when required easy and quickly be dismantled. Only one pump has to be used for the mounting/dismantling.

The extremely high torque which can be transmitted is mainly due to the fact that ETP has succeed in increasing the coefficient of friction (μ) between the contact surfaces which transmits the torque. The normal coefficient of friction μ between metallic surfaces is 0.15. With the application of a specially developed surface treatment called ETP-HFC (High Friction Coating), the contact surfaces are coated with extremely hard metallic particles. The hard and protruding particles, which have penetrated and become part of the ground material, gives an increase of the coefficient of friction to μ = 0,30.

ETP-HYCON is in the standard range coated with ETP-HFC on the inside. ETP-HYCON (excl. the flange joint for type F and FX) is type approved by DNV for marine applications. Patent is applied for.3 The increased coefficient of friction means that the same torque, as without coating, can be transmitted with a shorter and thus lighter coupling (S and F types) or that a considerable higher torque can be transmitted (SX and FX types).

ETP-HYCON is used for example in the ship building-, steel-, paper- or other heavy industry where the requirements are for high performance in combination with compact design, low weight, low polar moment of inertia, high rigidity and short down time.

Specification

- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

- About

- Support

- Others

- ACE PILLAR Subsidiary Website