- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

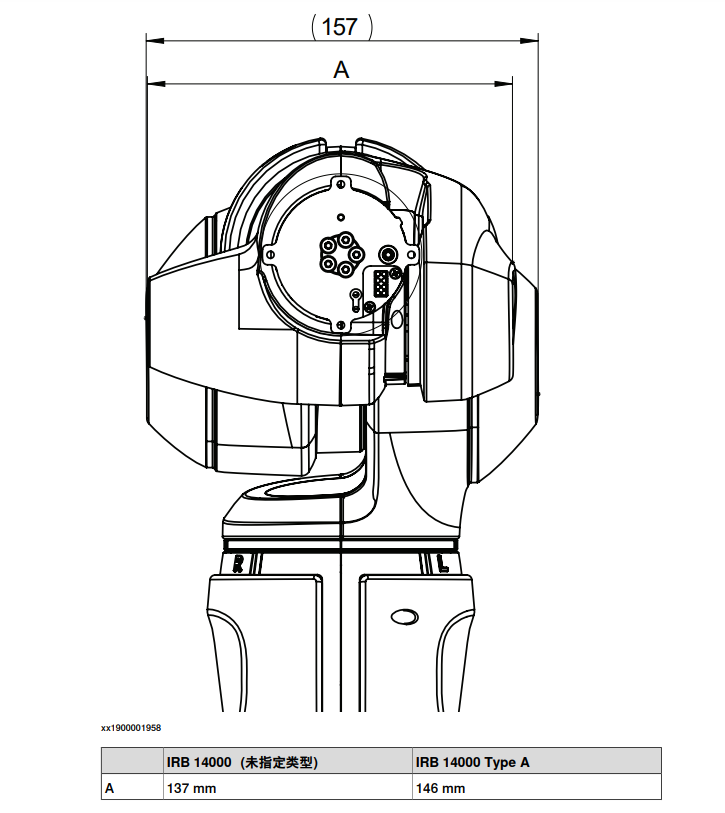

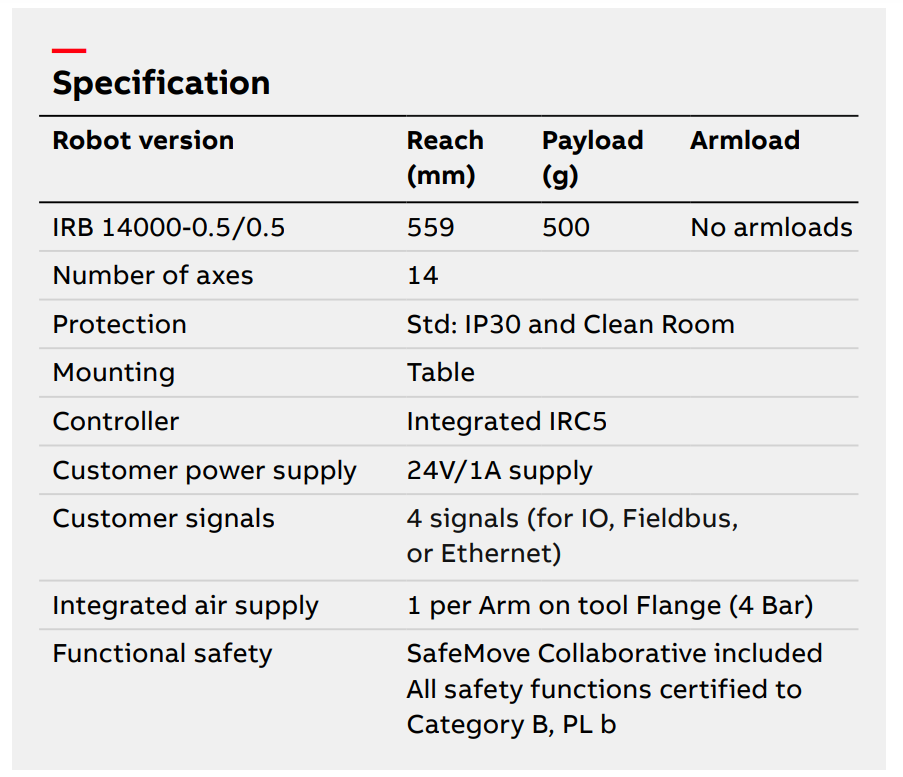

IRB 14000 YuMi® Collaborative Robot

Inherently safe, trulycollaborative. You and me.

YuMi is the first truly collaborative dual-armed robot, designed for a world in which humans and robots work together. It heralds a new era of robotic coworkers which are able to work side-by-side on the same tasks as humans with extreme accuracy while ensuring the safety of those around it.

Collaboration

YuMi is designed to meet the flexible and agile production needs required for small parts assembly in the electronics industry. It is also well suited to other

small parts environments, including the manufacture of watches, toys and automotive components.

All of this thanks to its dual-arms, flexible hands, universal parts feeding system, camera-based part location and stateof-the-art motion control.

Redefining safety

YuMi has a lightweight yet rigid magnesium skeleton covered with a floating plastic casing wrapped in soft padding, which absorbs the force of any unexpected impacts to a very high degree. YuMi has no pinch points so that sensitive ancillary parts cannot be crushed between two opposing surfaces as the axes open and close.

If YuMi senses an unexpected impact or change in its environment such as a collision with a coworker, it can pause its motion within milliseconds to prevent injury, and the motion can be restarted again as easily as pressing play on a remote control.

YuMi is very precise and fast, returning to the same point in space over and over again to within 0.02mm accuracy and moving at a maximum velocity of 1,500mm/sec. This ensures the safety of human coworkers on production lines and in fabricating cells.

Total solution concept

ABB also develops software and manufactures hardware, peripheral equipment, process equipment and modular manufacturing cells. This “total solution” concept is evident in YuMi’s breakthrough design.

Features

- The fifth-generation, integrated IRC5 controller with

- TrueMove and QuickMove™ motion control technology commands accuracy, speed, cycle-time, programmability and synchronization with external devices.

- I/O interfaces include Ethernet IP, Profibus, USB ports, DeviceNet™, communication port, emergency stop and air-to-hands. YuMi accepts a wide range of HMI devices including ABB’s teach pendant, industrial displays and commercially available tablets.

- The 100–240 volt power supply plugs into any power socket for worldwide versatility

Specification

Download

- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

- About

- Support

- Others

- ACE PILLAR Subsidiary Website