- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

SFF Models

These couplings have disc springs that use steel for the body. This makes them optimal for ordinary feed shafts that have high torsional stiffness, have accurate shaft rotation, and are capable of ultra-precise control. Both single-element types with high torsional stiffness and flexible double-element types that separate double elements with a spacer are available.

Friction coupling compatible with large diameters

Unlike past models of the frictional coupling type, these have no guide on the sleeve periphery to increase the precision of insertion, so they can handle large-diameter shafts.

Reliable shaft coupling

Since frictional coupling is used to mount on shafts, you can achieve high coupling strength simply by fastening the pressure bolts at the end surface of the flange, in order. They can also be mounted without drag turning by sticking a rod or the like into a hole drilled into the outer circumference of the flange.

Supports wide range of shaft dimensional tolerances

The basic class for the shaft dimensional tolerances is h7, but a wide range is supported, including k6, m6, and j6.

Pre-assembled Products

The flanges at the two sides of the coupling are assembled using a dedicated, high-precision tool, ensuring a high degree of concentricity. This helps shorten assembly time for the customer..

Clean room compatible

It is a clean room compatible product that has been cleaned, assembled (ISO class 6) and packed in consideration of its use in clean rooms.

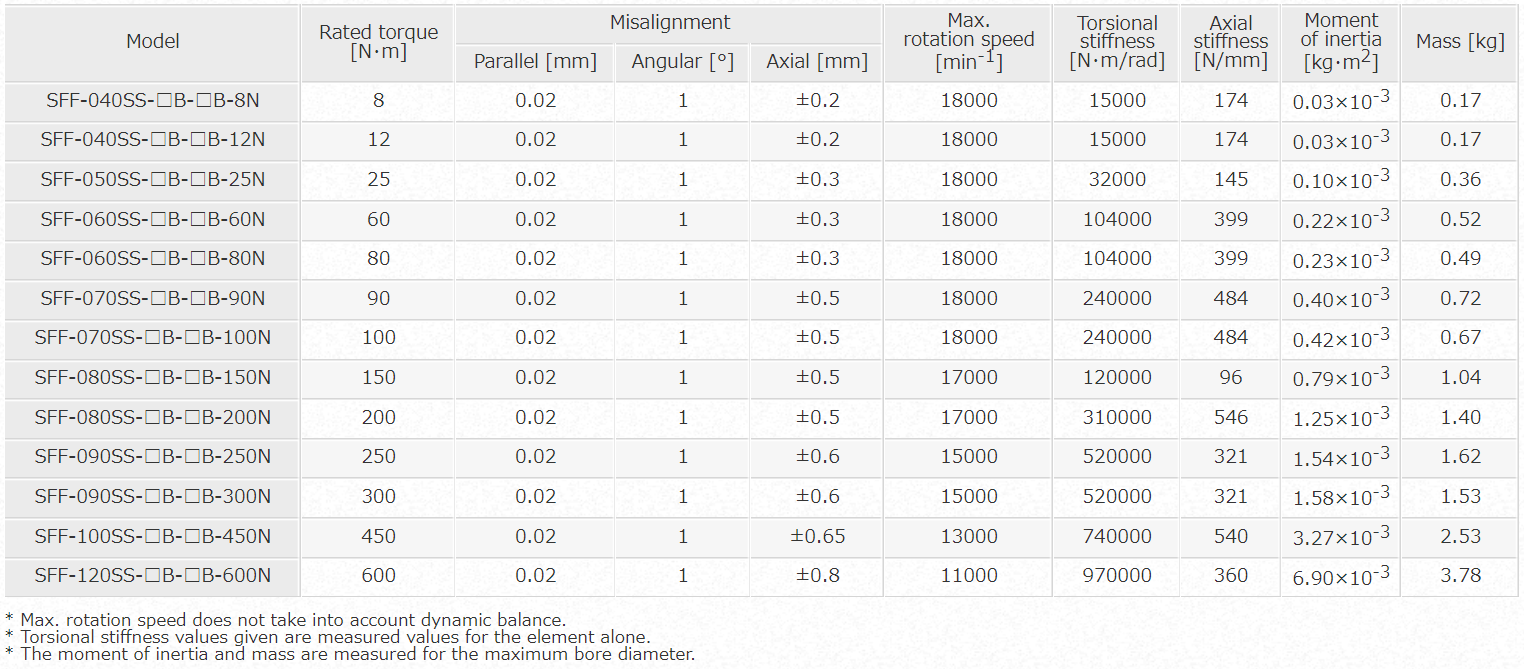

SFF-□SS (Clamping)

[Specifications]

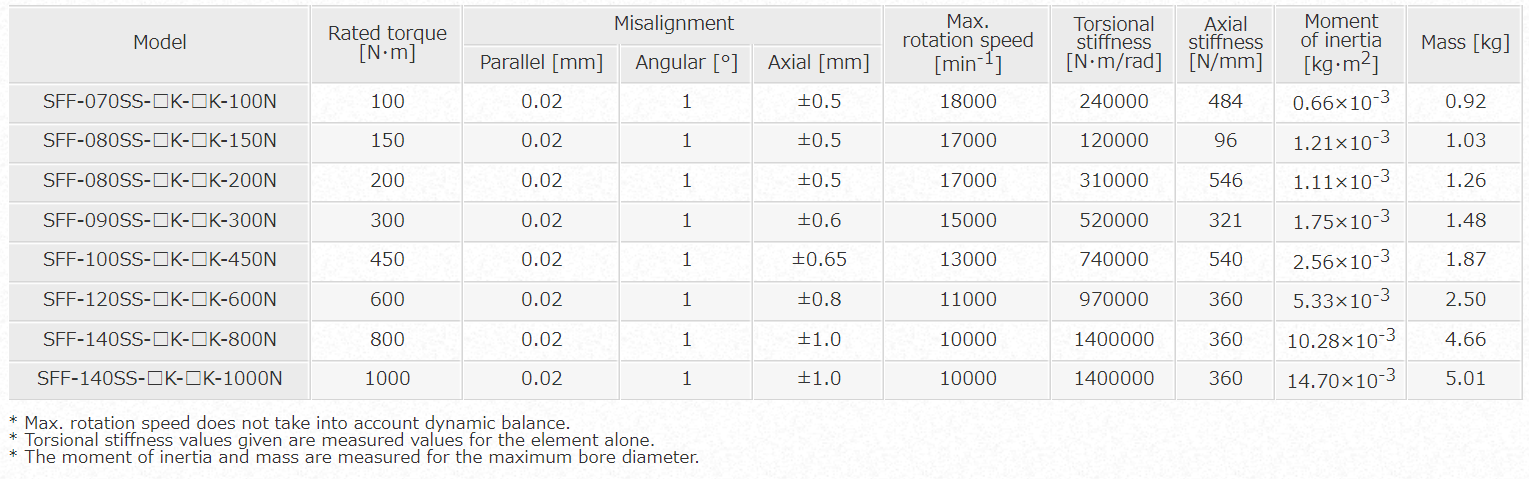

SFF-□SS (Wedge Coupling)

[Specifications]

- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

- About

- Support

- Others

- ACE PILLAR Subsidiary Website