Robotic arms have become a widely debated topic in recent years, owing to the promotion of Industry 4.0, labor shortages caused by the 2019 pandemic, and the full-scale deployment of AI technology. Although robotic arms have been utilized in the mechanical sector for six or seven decades, the market for them is still quite competitive, with technologies and application domains constantly evolving.

The extensive use of robotic arms has made them an essential piece of equipment in modern manufacturing. Robotic arms have proven efficient in improving production efficiency, lowering labor costs, and improving product quality in a variety of industries, including automotive and electronics manufacturing. As technology progresses, the flexibility and intelligence of robotic arms improve. For example, robotic arms outfitted with AI visual recognition algorithms may do complicated jobs more precisely.

Delta Custom Arm Controller: Supporting Various Kinematic Configurations

The current robotic arm options on the market cannot meet all demands. Some businesses demand highly customized solutions to meet specific manufacturing requirements and processes. This is where customised robotic arm solutions come into play.

In addition to ordinary robotic arms, there are robotic arm controllers with built-in kinematics for a variety of unique arm structures. These are integrated into a unique arm controller, enabling industry leaders to swiftly and easily create their own custom robotic arms.

The most important thing everyone wants to know is what types of kinematic configurations are available:

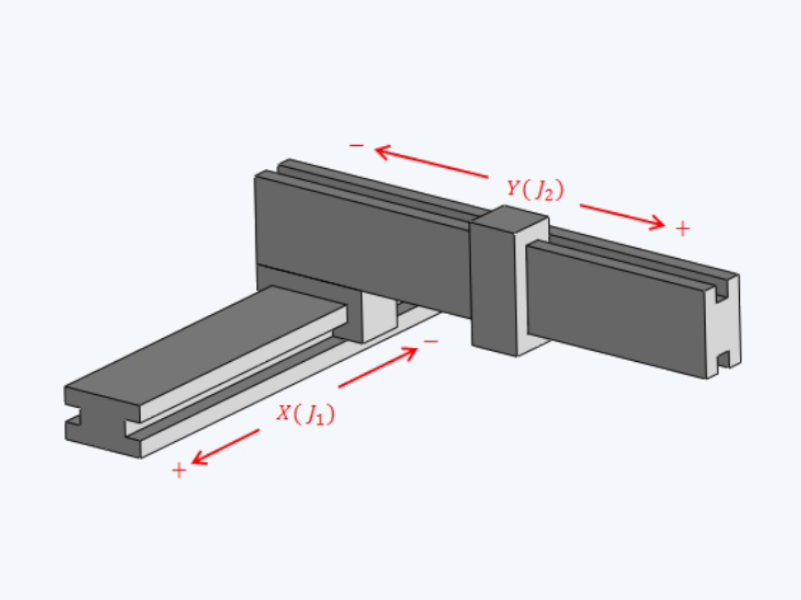

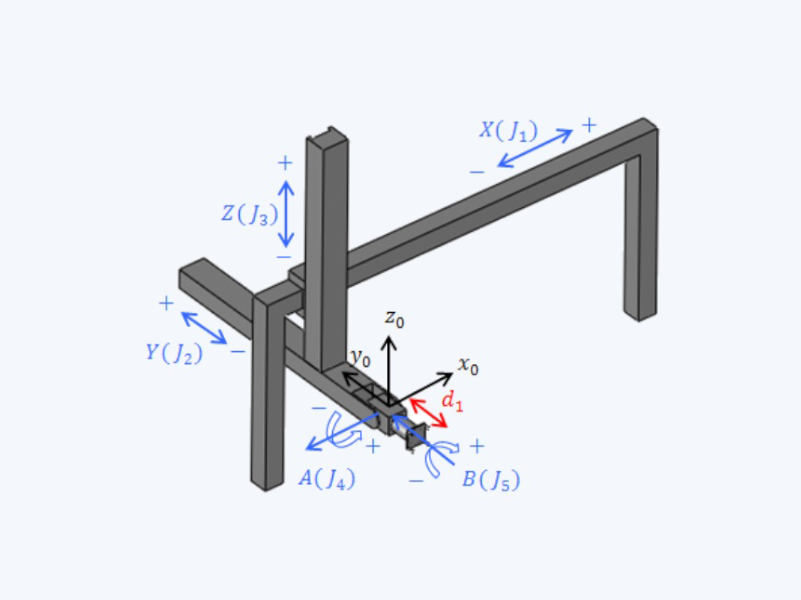

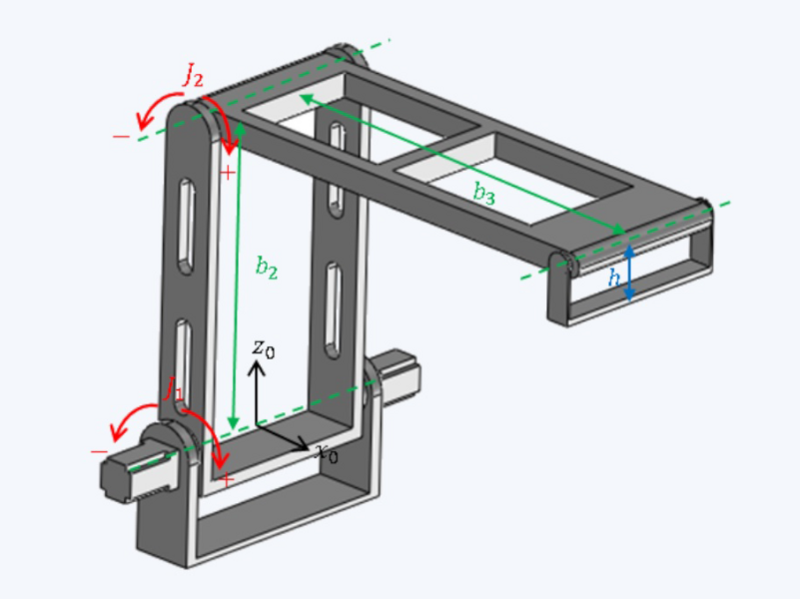

Two to Five-Axis Cartesian Coordinate Systems:

Similar to a rectangular coordinate system, they are ideal for traditional handling and positioning operations.

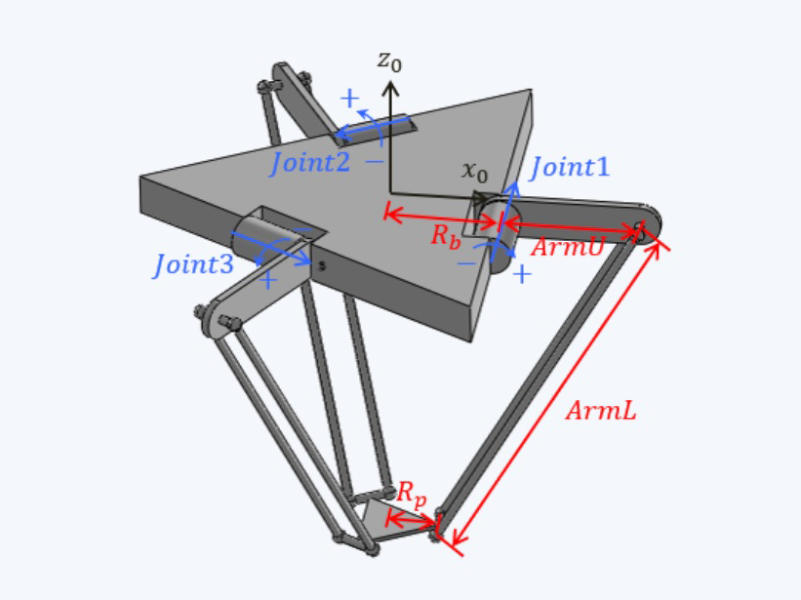

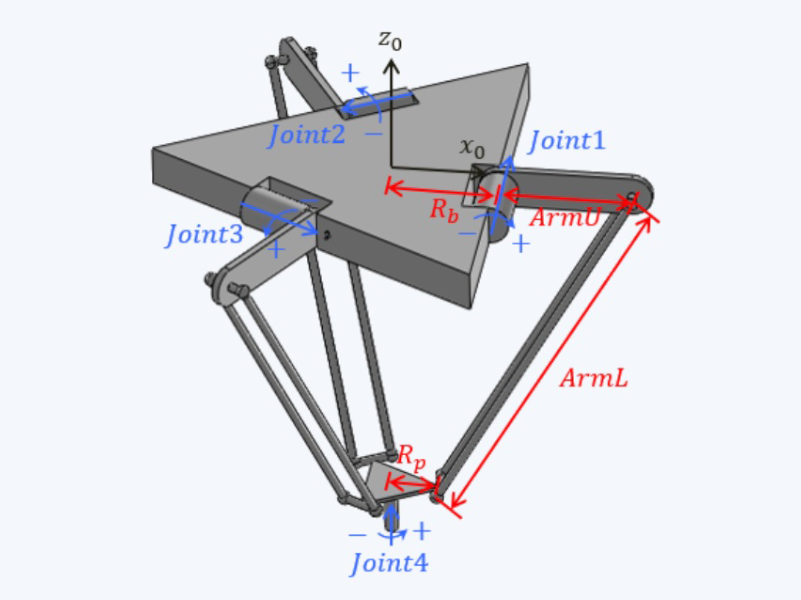

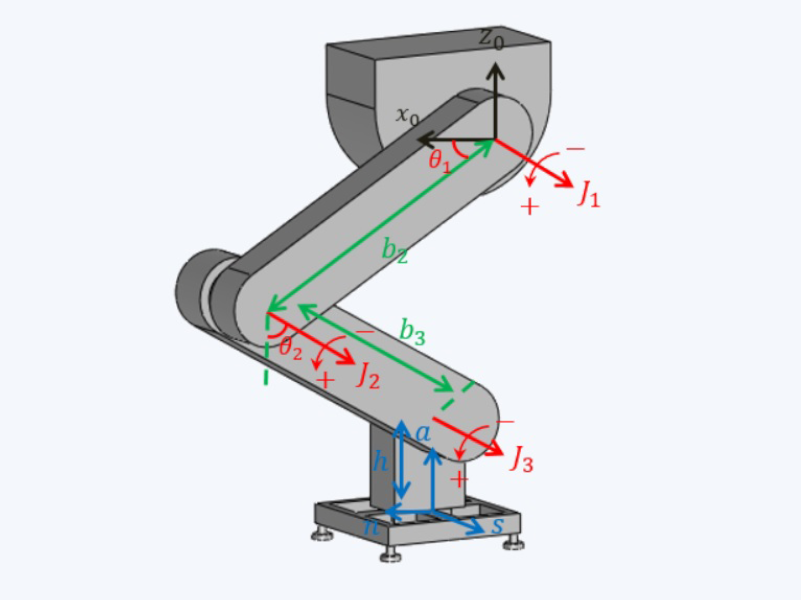

Two to Five-Axis Delta Robots:

Known for the fastest horizontal pick-and-place operations, commonly referred to as spider arms.

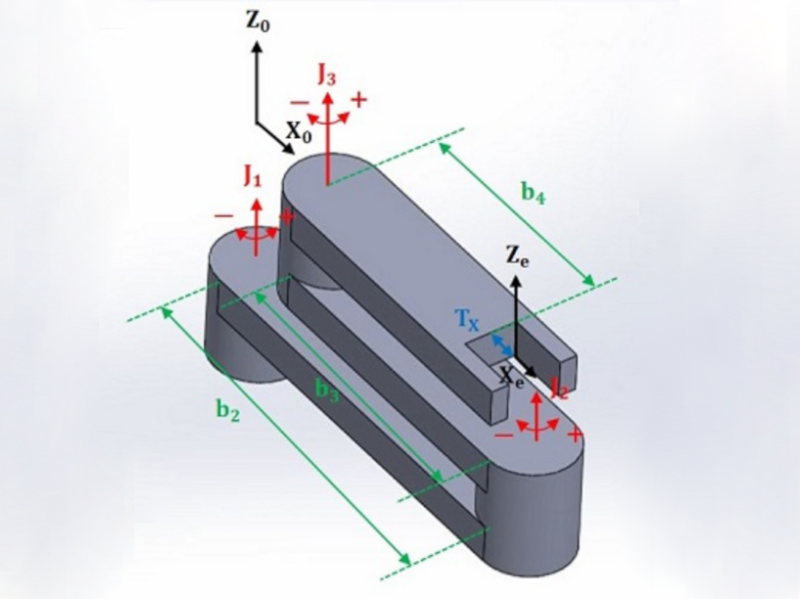

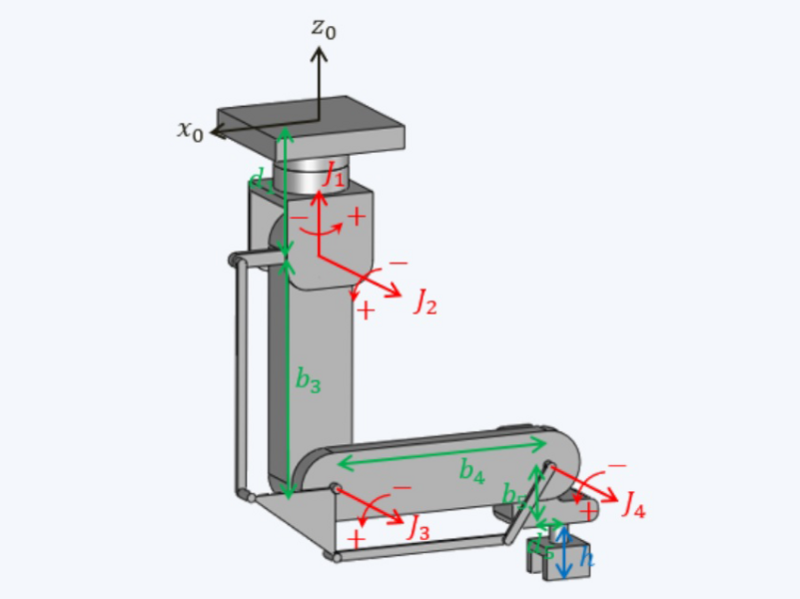

Two to Six-Axis SCARA:

These types of robotic arms possess both rotational and vertical movement capabilities, making them ideal for high-precision assembly and pick-and-place operations, commonly used in the electronics and semiconductor industries. Currently, the most frequent applications among clients involve wafer handling or cassette pick-and-place operations.

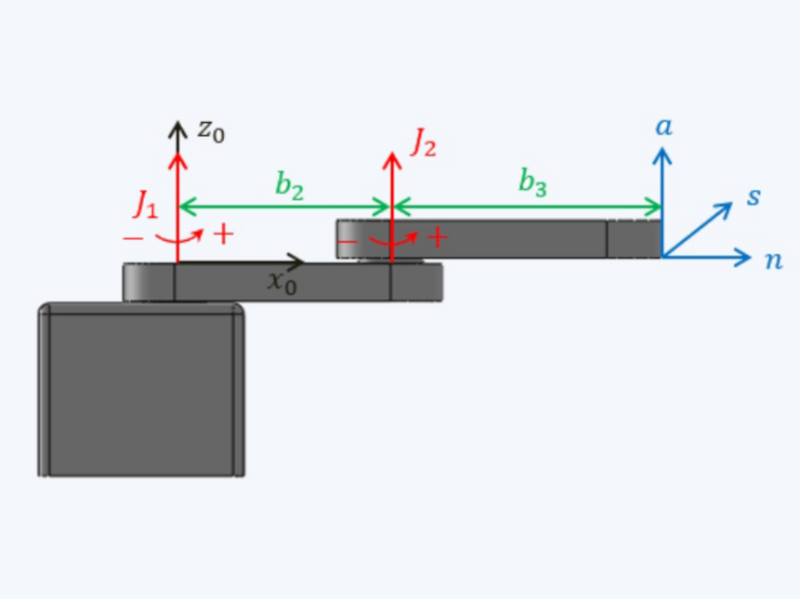

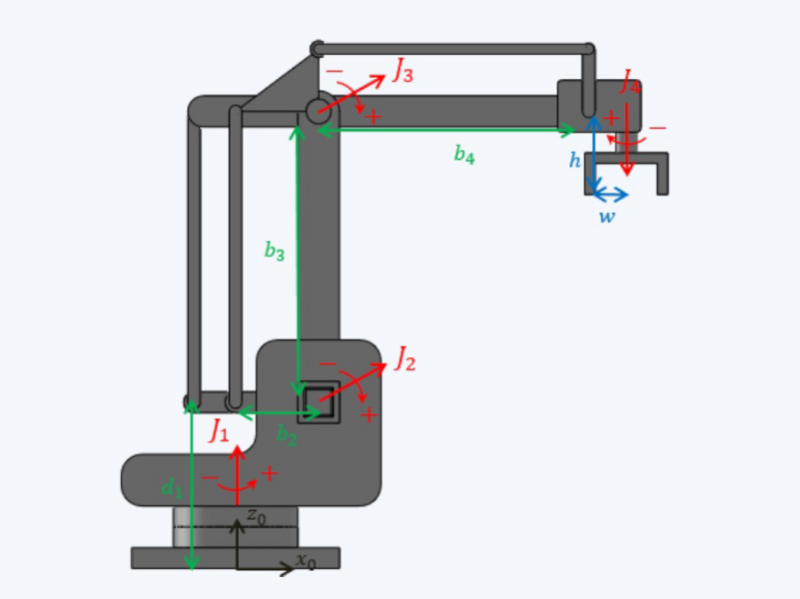

Two to Five-Axis Cylindrical Configuration:

In this configuration, the robotic arm operates within a cylindrical coordinate system, offering circular and vertical motion. It is well-suited for tasks such as stacking objects, flipping items, and other similar operations.

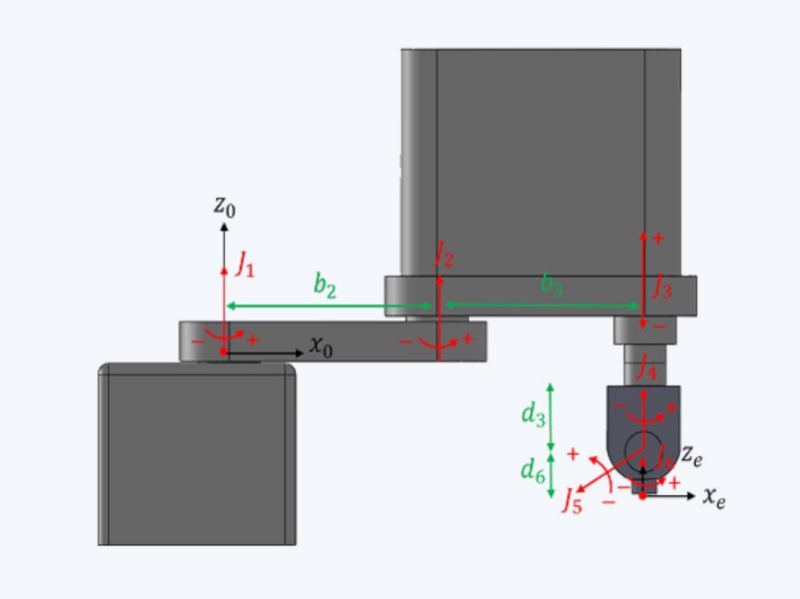

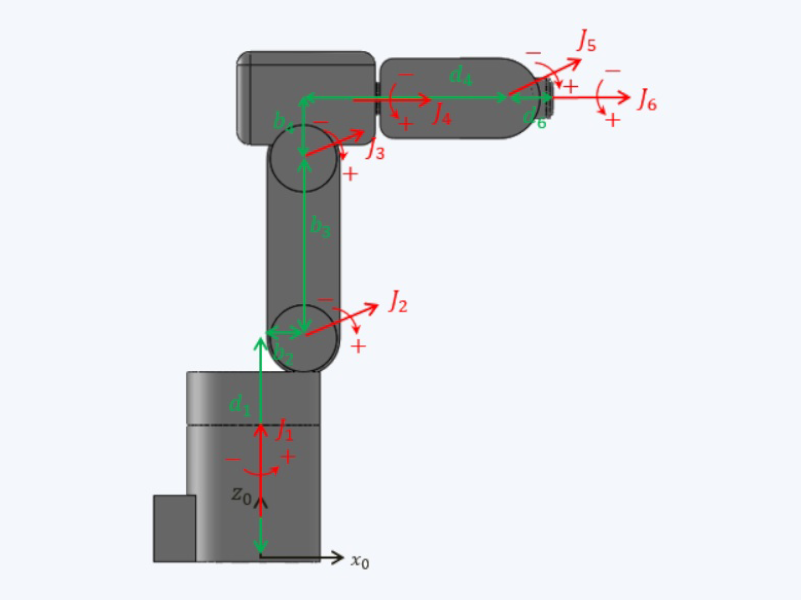

Articulated with Three to Seven Axis:

This type of arm is similar to a human arm, with multiple rotating joints, offering high flexibility. If the picking and placing position and angles are straightforward, a simplified configuration with fewer axes can be chosen. If more complex positional and angular movements are required, configurations with more axes are available, suitable for various industrial applications.

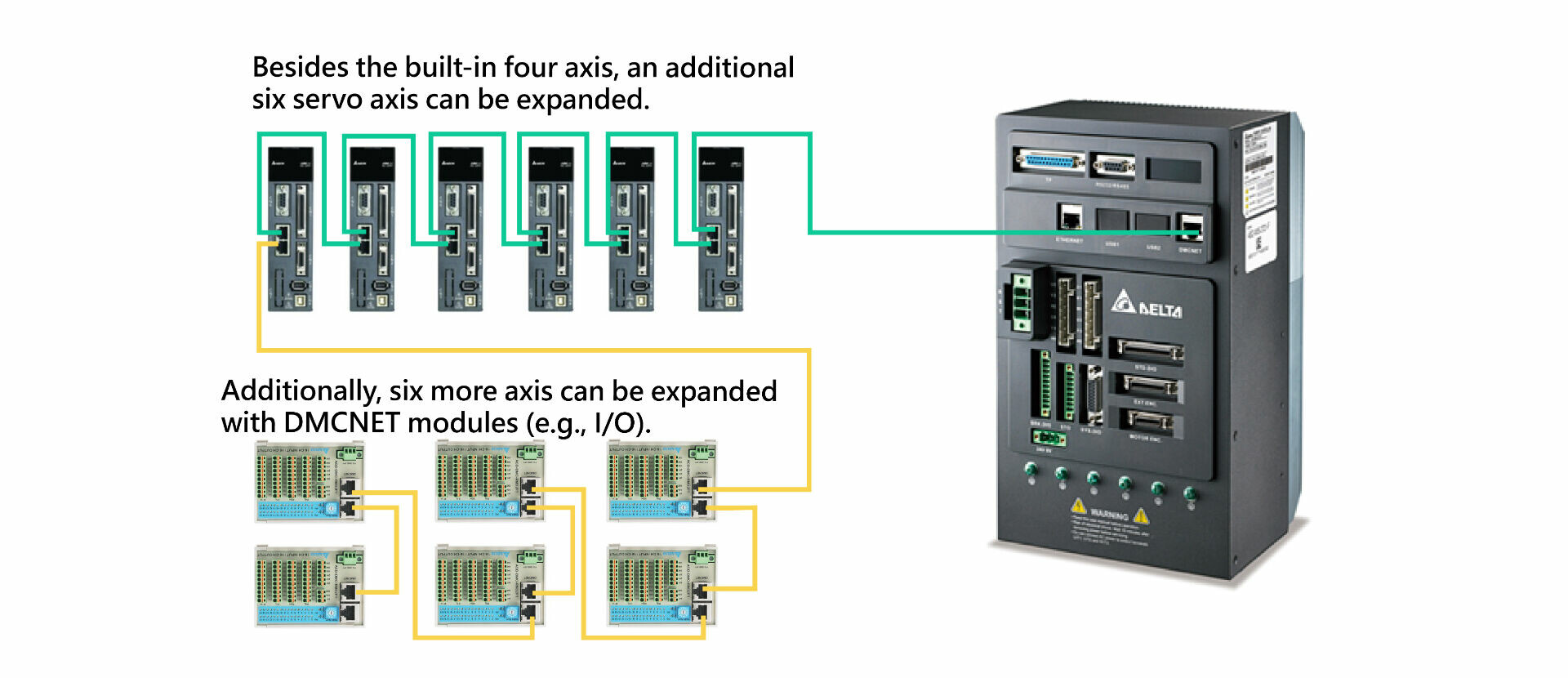

ASDA-MS Controller Expandable Network Digram

The ASDA-MS controller configuration supports up to four axes locally (with options ranging from 100W to 750W) and can be expanded to control up to six axes (with options ranging from 100W to 15kW) and six I/O modules. The primary advantage of using an arm controller is its ability to automatically convert servo motor revolutions into spatial coordinates based on the arm length and servo reducer ratios designed by the customer. With properly and accurately designed peripheral mechanisms, this system minimizes the need for calibration points and allows for precise movement to multiple positions using offset commands, enhancing operational convenience.

Total Product Line and Expert Application Assessment by Ace Pillar

In today's quickly changing production landscape, choosing the proper robotic arm solution is critical. With constant advancements in automation technology, every detail on the production line has the potential to effect overall performance. Ace Pillar experienced service team can provide customized robotic arm controllers and system configurations to meet your individual demands, ensuring that production requirements are satisfied while maximizing efficiency and product quality. Whether you have complex multi-axis kinematic configurations or custom needs for unique manufacturing processes, our skilled team can give optimized solutions based on your individual circumstances.

Recommended products