Enhancing Test Accuracy with Gantry Structure

Precision wafer placement is essential for pre-encapsulation detection and testing. It frequently faces the issue of misjudging good-quality chips as defective (Overkill), forcing retesting. The extra time spent leads in lower manufacturing efficiency, making it a challenging position.

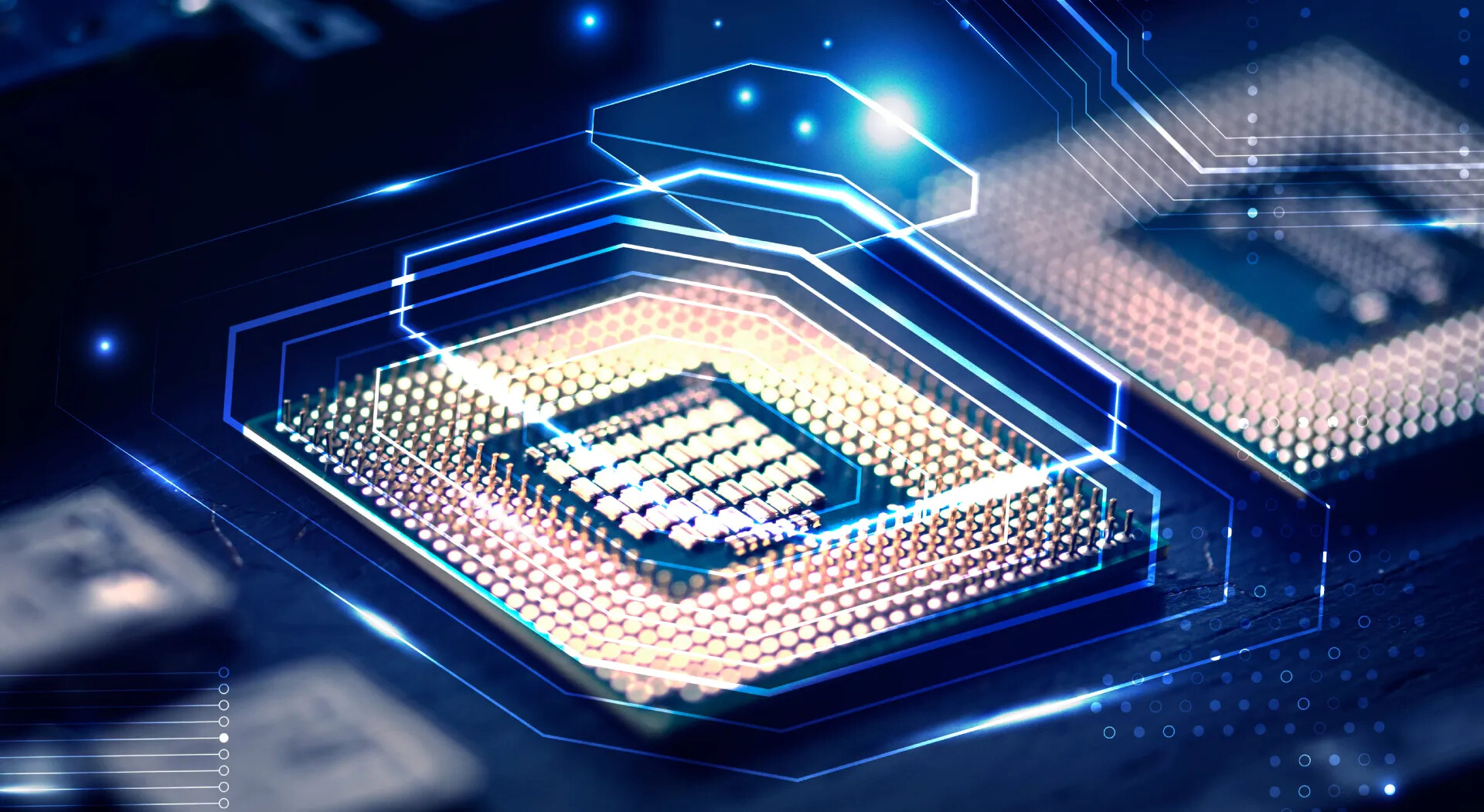

Conducting probe testing on semiconductor wafers is a crucial phase in ensuring product yield once semiconductor wafer production is completed. The probe perfectly aligns itself within the X and Y planes of the wafer before vertically positioning along the Z-axis to reach the predefined test locations during this electrical measuring process. Input signals are then applied, setting off a continuous testing operation. After collecting feedback data, the product's quality is identified.

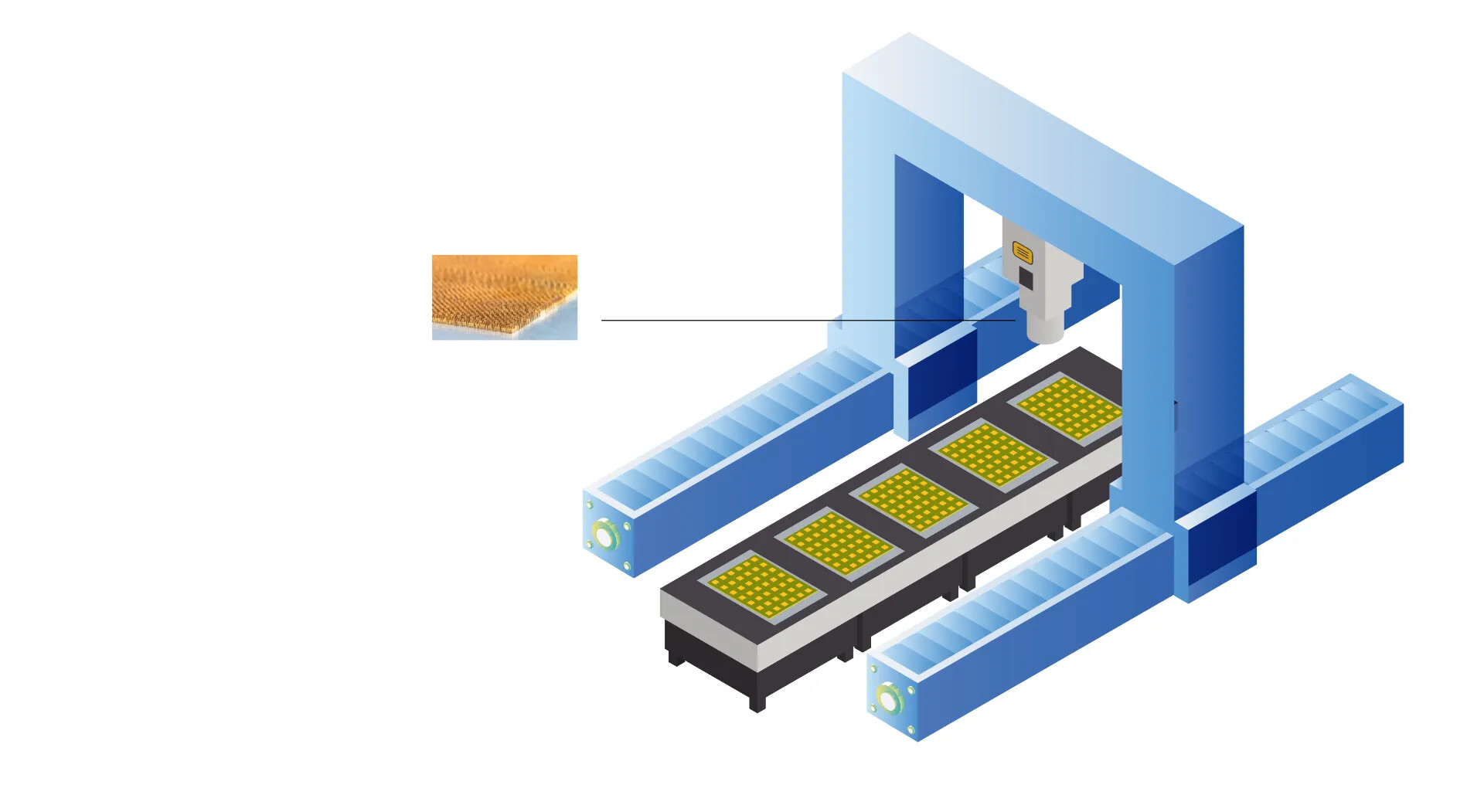

Operators who are inexperienced with the equipment during probe testing may dramatically reduce test accuracy. To address this, a gantry structure was created to ensure 100% stability during probing and electrical measurements while also reducing overall testing complexity. Customers can use this design to precisely position wafers in the X and Y planes, ensuring the stability and precision of semiconductor wafer probing.

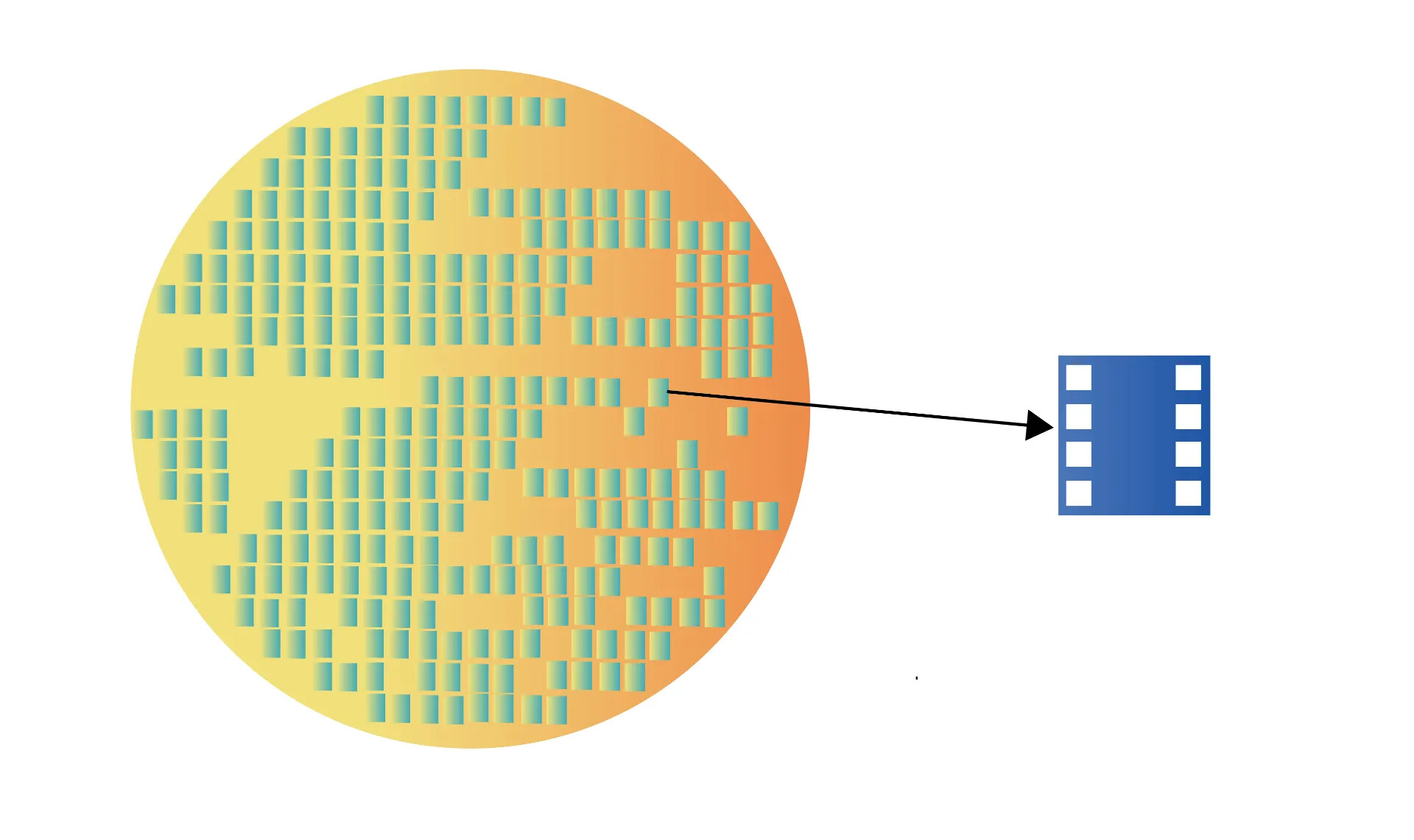

Diagram depicting the relationships between probes, electrical contact points, grains, and wafers in wafer testing.

What exactly is Dual-drive gantry stage?

"Simply put, it means each axis controls a motor, and the two motors move and stop together, jointly controlling the same mechanical axis." (For additional information on gantry synchronous motion, see this article.)

The pain points and solution

The Dual-drive gantry stage is a perfect option, providing extremely high machine precision and accurate alignment capabilities. It is ideal for applications requiring the testing of an extensive amount of organized components. When combined with diverse program development and equipment planning, it enables equipment developers to quickly delve into semiconductor applications, fulfilling client demands for precise motion control and load requirements.