Innovative Solutions for Reducing Carbon Emissions in High-Energy Manufacturing

Leveraging Data for Sustainable Innovation: Paving the Way for the Future of Environmentally Friendly Manufacturing.

ESG (Environmental, Social, and Governance) has grown in significance in recent years, capturing the attention of global corporations and publicly traded companies. Taiwan's government, too, has taken proactive steps to ensure compliance with the international 2050 emissions-free target. It has strongly embraced ESG concepts, devised novel solutions, and acknowledged the pursuit of environmentally responsible activities as a common worldwide goal.

Companies in this setting have expanded their concerns beyond earning profits. They are now heavily involved in environmental, energy, and social issues. These firms not only include sustainability factors into their own operations, but they also carefully examine the offerings of their upstream suppliers.

ACEPILLAR Co., Ltd. has established the standard for meeting low-carbon energy demands among upstream suppliers. In one case, they partnered with a high-energy-consumption punch press equipment manufacturing, introducing smart meters and creating an Energy Management System (EMS).

This strategic decision was made in order to reduce the factory's annual carbon dioxide emissions and excessive electricity usage as a result of its industrial activities. The installation of the EMS system now allows the factory's operating units to closely monitor energy use and carbon emissions, allowing for process improvements. As a result, the company is well-positioned to produce "low carbon products," improving its market competitiveness.

Energy Efficiency Optimization and Equipment Evaluation

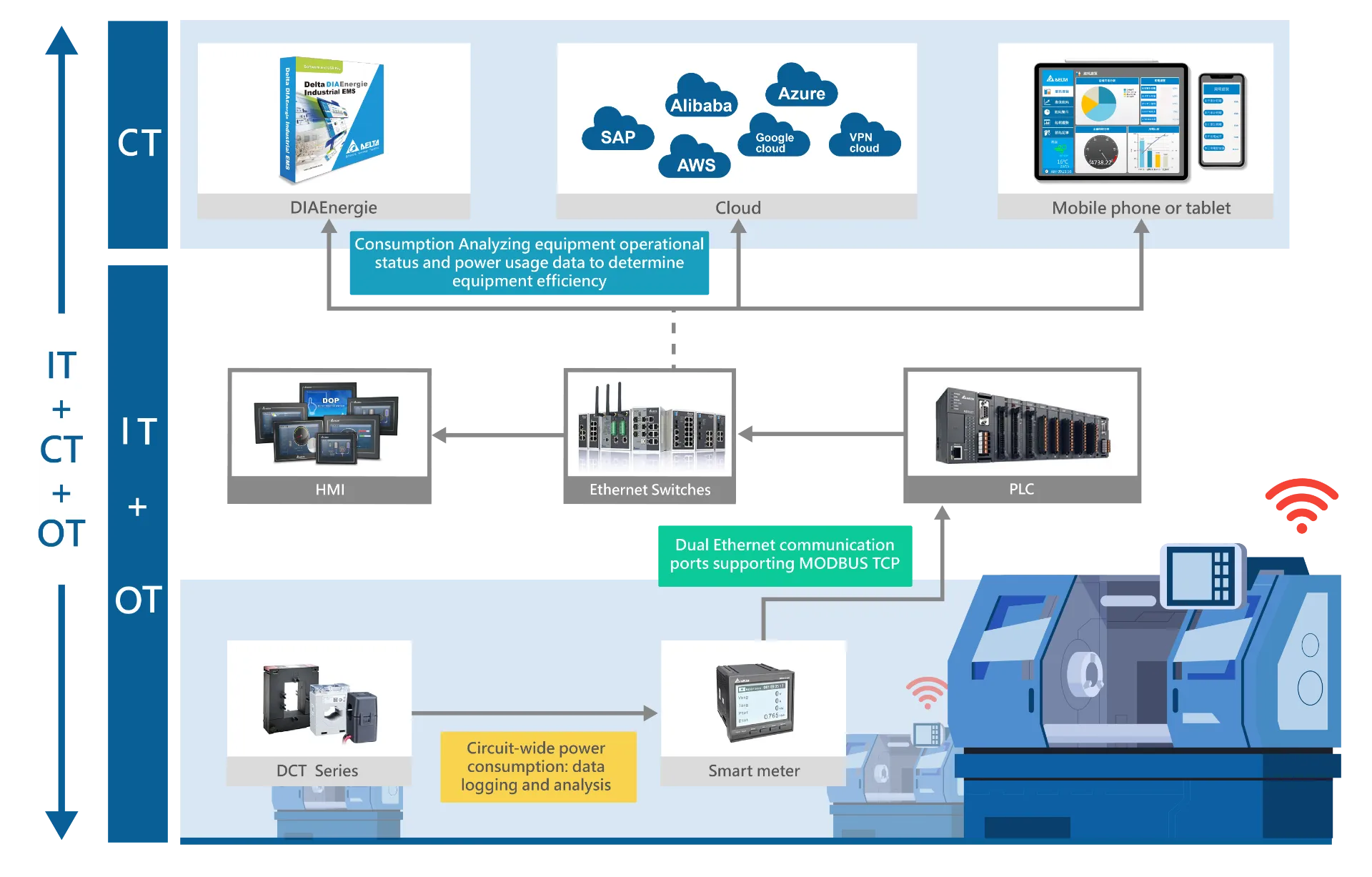

EMS examines the relationship between electricity consumption and equipment operational state, monitoring various electricity consumption trends to detect unusual equipment operation. An increase in unusual electricity use may indicate a malfunctioning piece of equipment, resulting in energy waste. When equipment anomalies occur, we can issue alerts to production supervisors via a mobile app and tablet.

Process Energy Efficiency Analysis and Electricity Consumption Estimation

Punching presses are manufactured using industrial manufacturing procedures. We provide a module for calculating carbon emissions and analyzing process energy efficiency. For example, if a given shape is pressed 100 times in 8 hours, we may determine the energy consumption and carbon emissions for each product through measuring the total electricity consumption and the electricity consumed for every single press.

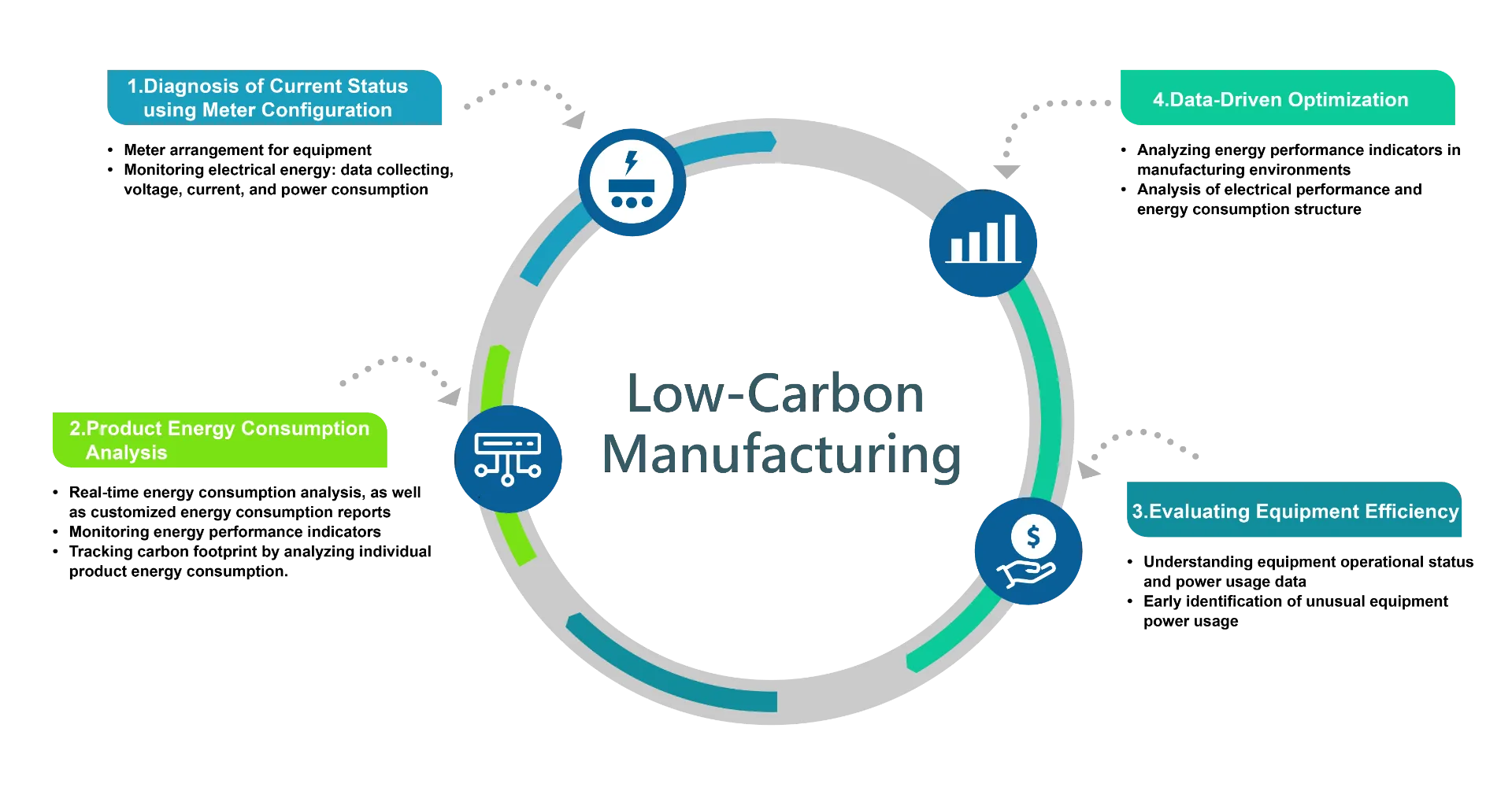

Contributing to the Achievement of Low-Carbon Manufacturing Goals

The EMS system effectively tracks electricity consumption across several channels by utilizing DPM series smart meters integrated on the equipment side. We enhance the detecting process to assure data precision by combining real-time monitoring systems.

ACEPILLAR Co., Ltd. conducts evaluations of green energy policy implementation within organizations to assure the sustainability of environmentally friendly businesses. Their integrated solutions include energy monitoring and the promotion of low-carbon manufacturing processes, making them a critical component in achieving business ESG (Environmental, Social, and Governance) goals. These help firms comply with ESG standards and meet the challenging 2050 net-zero carbon emission targets, bringing in a greener and more sustainable future.