A Technological Leap in Screw Assembly Efficiency

Life has a small screw that no one sees in every part of it. Every day, we depend on them. It doesn't matter if they're small screws in our phones or big ones in factories and cars. Putting screws together has always needed a lot of manual work. Because screws come in different shapes, sizes, and materials, the force needed to tighten them also changes.

How can people be sure that screws are tightened correctly? As the first step, it's very important to place the screws correctly and tighten them down. In the next step, it's very important to use the right amount of force and put it exactly where it needs to be during the tightening process. To improve quality and keep damage to a minimum, force must be carefully chosen and placed. Precision use of the screw that seems so small can make it work very well.

Diagram

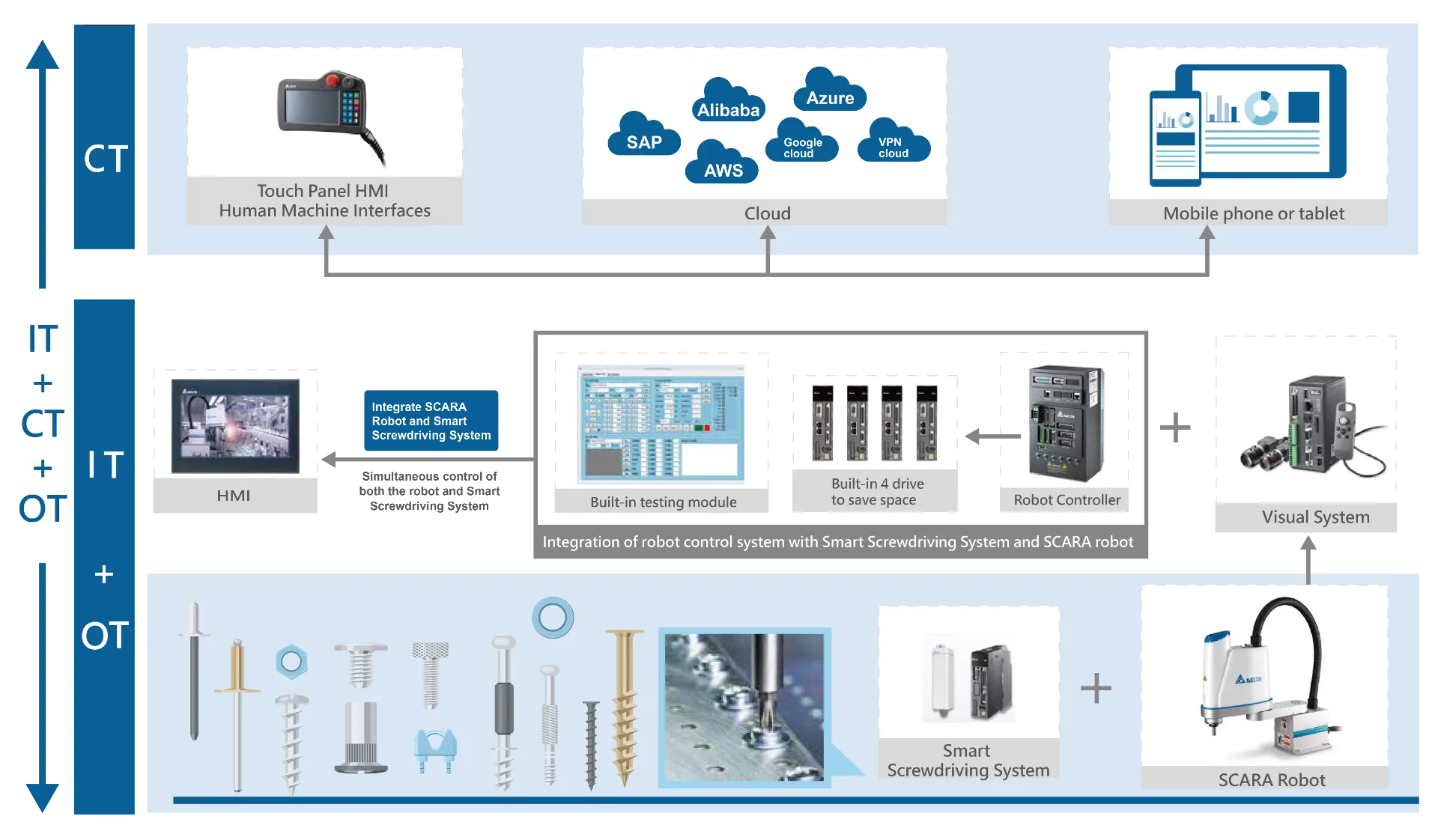

Delta Electronics has created The Delta Smart Screwdriving System which includes the SACRA robot, a visual system, and an electric lock module. This method fixes common problems with electronic screw locking tools, like screws not being tightened enough or being misaligned.

With its fourth axis, the "SCARA robot" optimizes screw-locking. It increases efficiency by removing one U-shaped rotational axis and replacing it with an electric lock module, which provides high precision and consistency. Users can simply control both the robot and the electric screw-locking mechanism using the visual system. This unified design promotes efficient drive and control systems, as well as compact wiring to conserve space. The usage of a universal transmission link enables flexible pairing with various visual modules. Mobile phones and tablets provide user-friendly adjustments, enabling flexible mixed-line production.

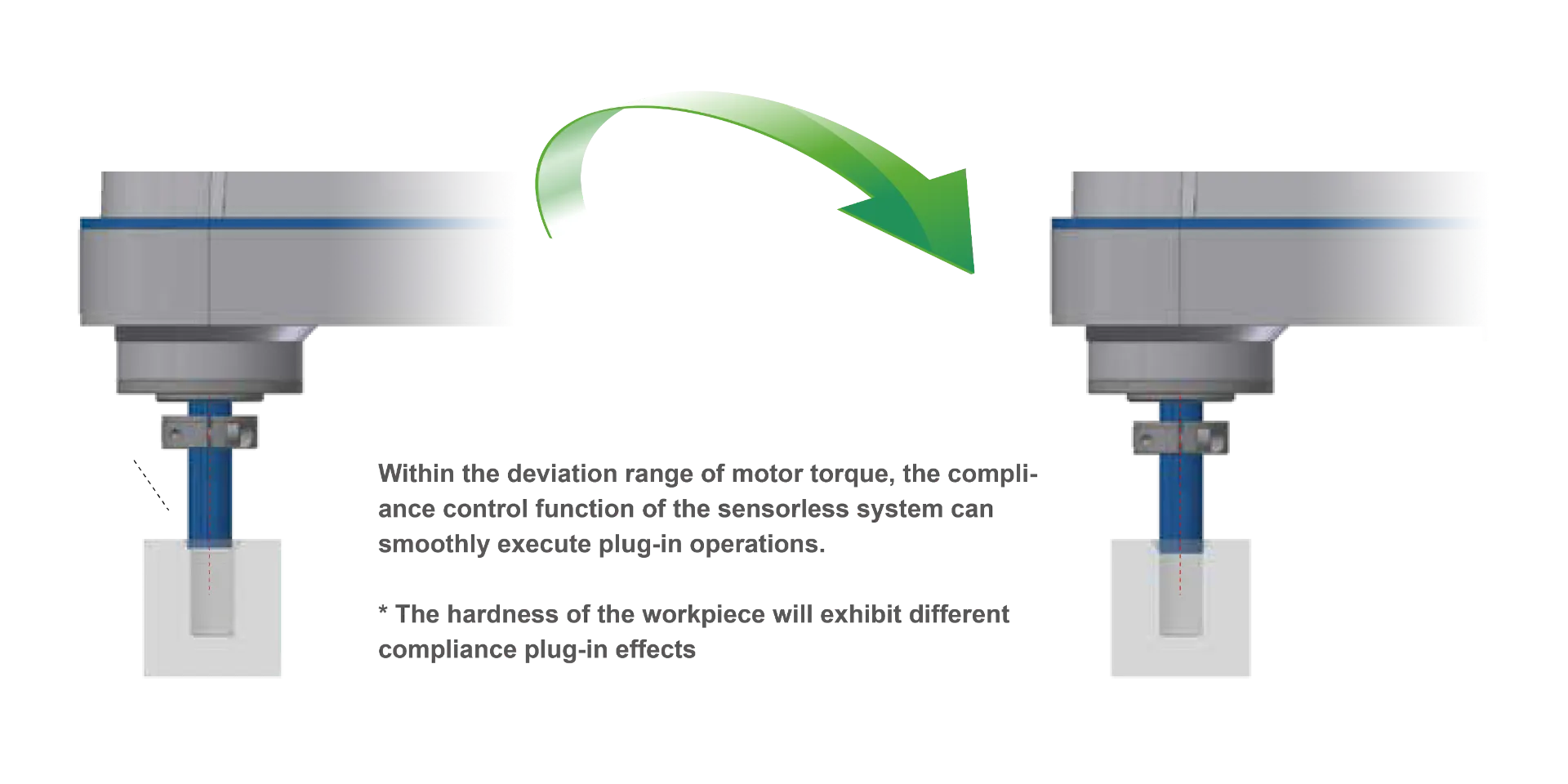

It features non-sensor adaptive control. This can adjust for differences in component and hole positioning.

The pain points and solution

Acepillar's Intelligent Automation Control and The Delta Smart Screwdriving System

The Delta Smart Screwdriving System offers a comprehensive solution for screw-tightening processes. It seamlessly integrates key technologies such as servo motors, torque detection, and software control, drawing upon Delta's extensive manufacturing expertise. The system is designed to meet the precision and quality requirements across a range of scenarios.

Utilizing cloud platforms to record real-time locking data, parameterize locking process information, and consistently enhance locking yield, Acepillar stands as a trusted partner with over 40 years of industry expertise in intelligent automation control. Recognized and praised by Delta Electronics, Acepillar has earned its reputation through extensive collaborations with both local and international partners, making it a compelling choice for those seeking a proven and reliable collaborator in the field.