In industries such as semiconductors, displays, and precision machining, micron-level alignment is key to enhancing productivity and yield rates. This Vision Alignment System integrates high-speed image processing with a flexible architecture to achieve automatic alignment and correction for a wide range of workpieces. It enables customers to significantly improve machining accuracy and reduce human error, paving the way for high-efficiency smart manufacturing.

Features & Advantages

Ultra-High Precision: Compatible with various optical lenses, achieving alignment accuracy up to 2μm.

Fast Processing Speed: Optical inspection time per cycle is under 50ms, accelerating the entire process.

Multi-Target Recognition: Supports alignment of circles, crosshairs, geometric shapes, and more.

User-Friendly Interface: Customizable interface design based on machine needs, lowering the learning curve.

Multilingual Support: Supports Traditional Chinese, Simplified Chinese, English, Japanese, etc.

Easy to Learn & Deploy: Intuitive setup process makes it ideal for operators with minimal training.

Flexible PLC Integration: Communicates with Delta PLCs and other major brands.

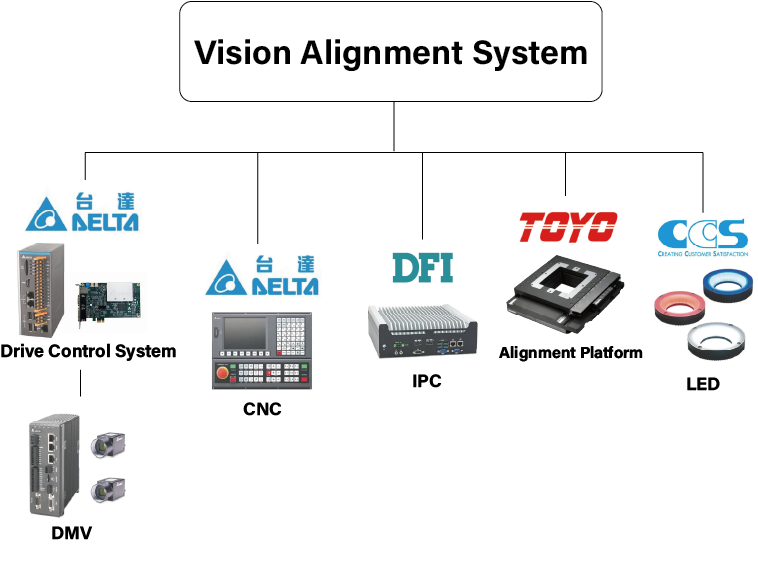

System Architecture

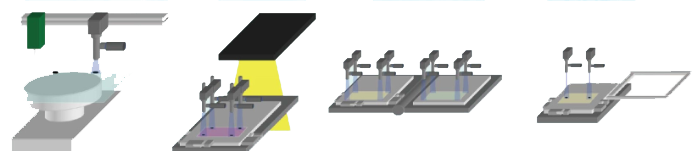

- Supports 1 to 8 cameras for flexible deployment in various scenarios.

- Maximum camera resolution up to 5 megapixels.

- Compatible with analog and digital camera types (GigE, CameraLink).

- Applicable to various alignment platform types: >()Y, ><YY, ><YQ, etc.

- Seamless integration with motion control cards and command-based control for motion platforms.

- Can be integrated with Delta CNC controllers to further enhance machining precision and yield.