With the development of modern technology, electric vehicles have grown into an increasingly popular means of transportation, and the associated charging demand has become a serious concern for electric vehicle users. When choosing a charging station, consider charging speed, interface type, and installation site.

This article will offer you with a simple guide to assist you in selecting the best charging station, ensuring that your electric vehicle always has enough juice.

Step 1 Understand the Charging Speed Requirements

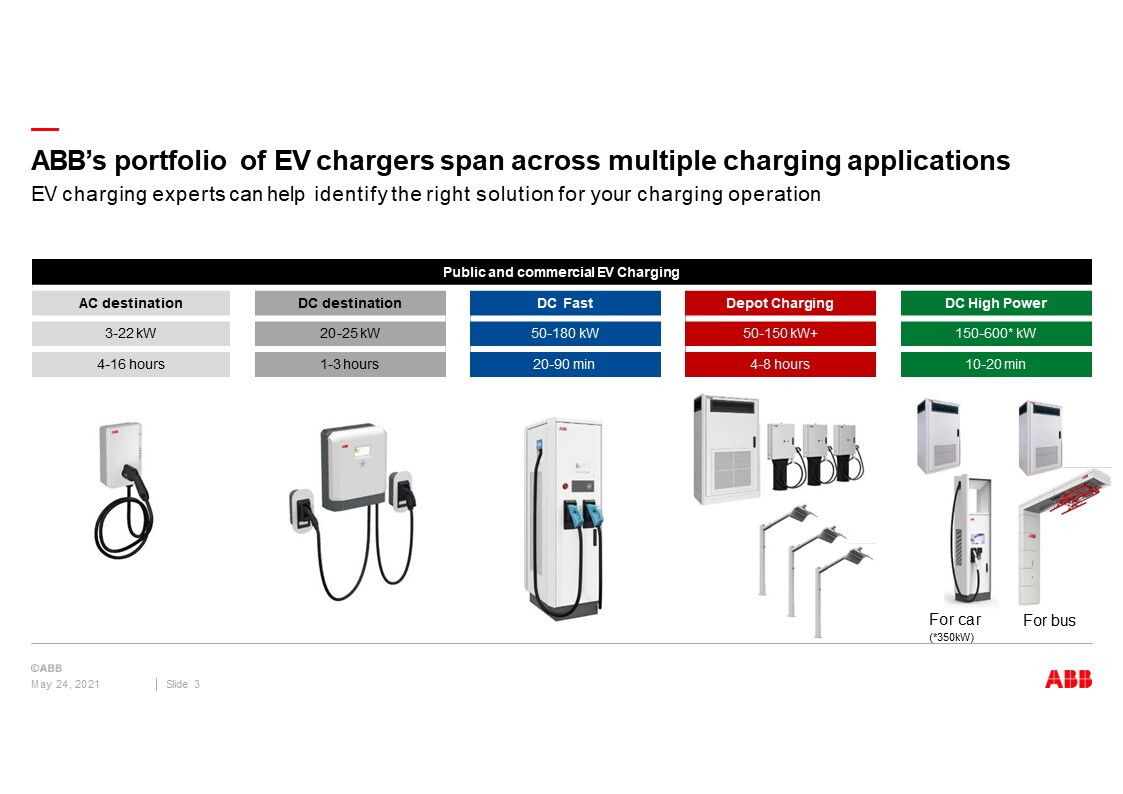

Charging periods range from 10-20 minutes to 4-16 hours, and charging power ranges from 3-22kW to 20-360kW.

First, you must determine your daily charging requirements. If you drive great miles every day, charging speed becomes an important consideration. Charging speed is usually expressed in kilowatts (kW). A conventional household plug may only provide a slower charging speed (often between 2-3 kW), but specialist high-power charging stations can deliver charging speeds of 50 kW or greater. Understanding the maximum charging speed supported by your electric car is critical for selecting the appropriate charging station.

Step 2: Select the Interface Type and AC/DC Power Supported

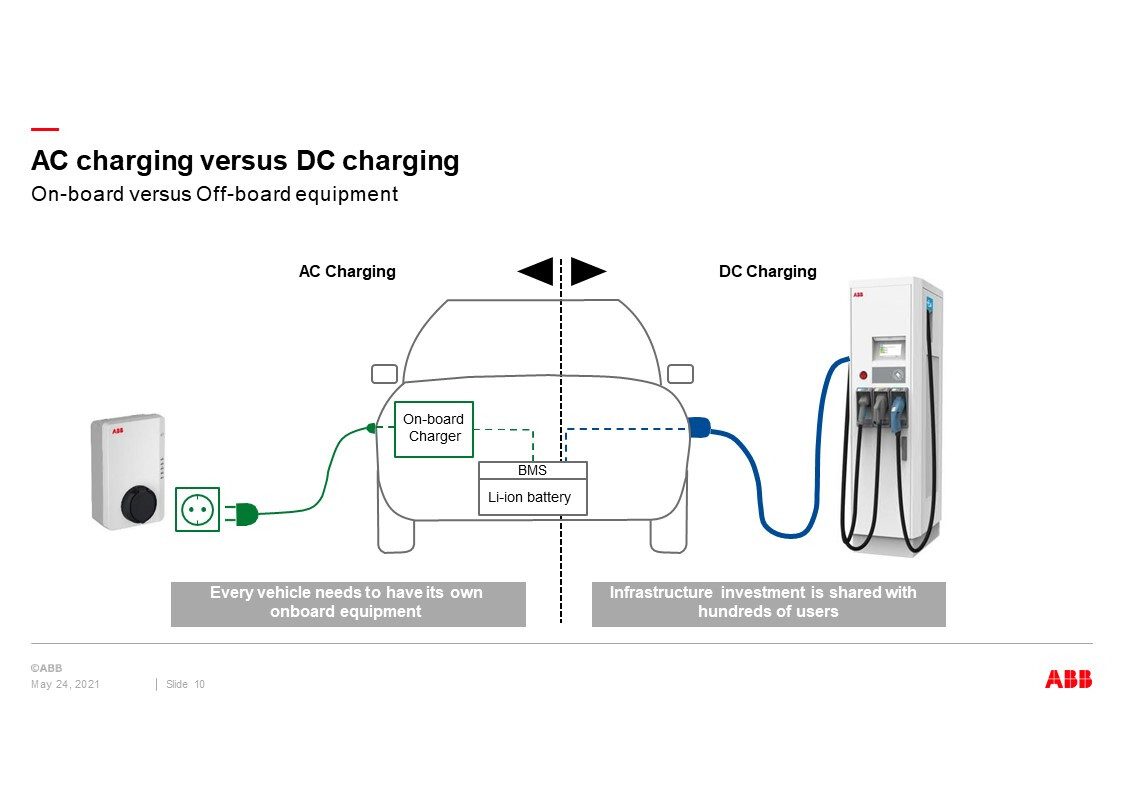

Please confirm the charging interface protocol of the electric vehicle as well as the maximum AC charging power supported by the electric vehicle.

Different electric vehicle manufacturers may employ various charging interface types. CHAdeMO, CCS (Combo), and Tesla's NACS (North American Charging Standard) are presently the most prevalent charging interface types. When purchasing charging stations, ensure that they have more than one type of interface so that they may function with various types of electric vehicles at home or at work.

How much power may be utilized for charging is determined by how well the electric car's generator functions. Be aware of the maximum AC charging power supported by the current electric vehicle.

Step 3: Consider Installation Locations

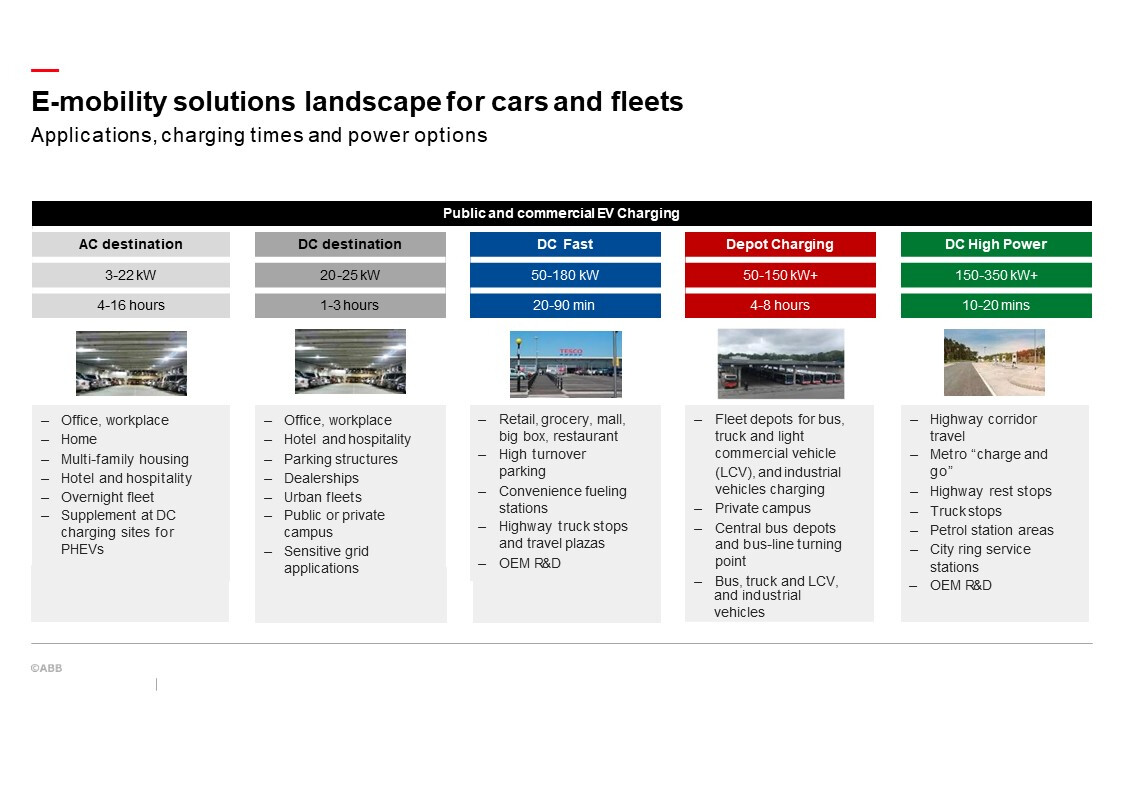

Home, workplace, medical institutions, parking lots, campuses, supermarkets, rest spaces, and charging stations are all examples.

Choosing the best placement for charging stations is a critical step. Most people choose to put charging units in their homes or places of work so they can easily charge their devices every day. Consider placing a charging station in your garage or parking spot if you own a home. Working with the neighborhood committee is needed to set up charging stations if you live in a building with a shared parking lot. Check that the chosen location has enough electricity and the appropriate safety measures.

Step 4: Take Scalability into Account

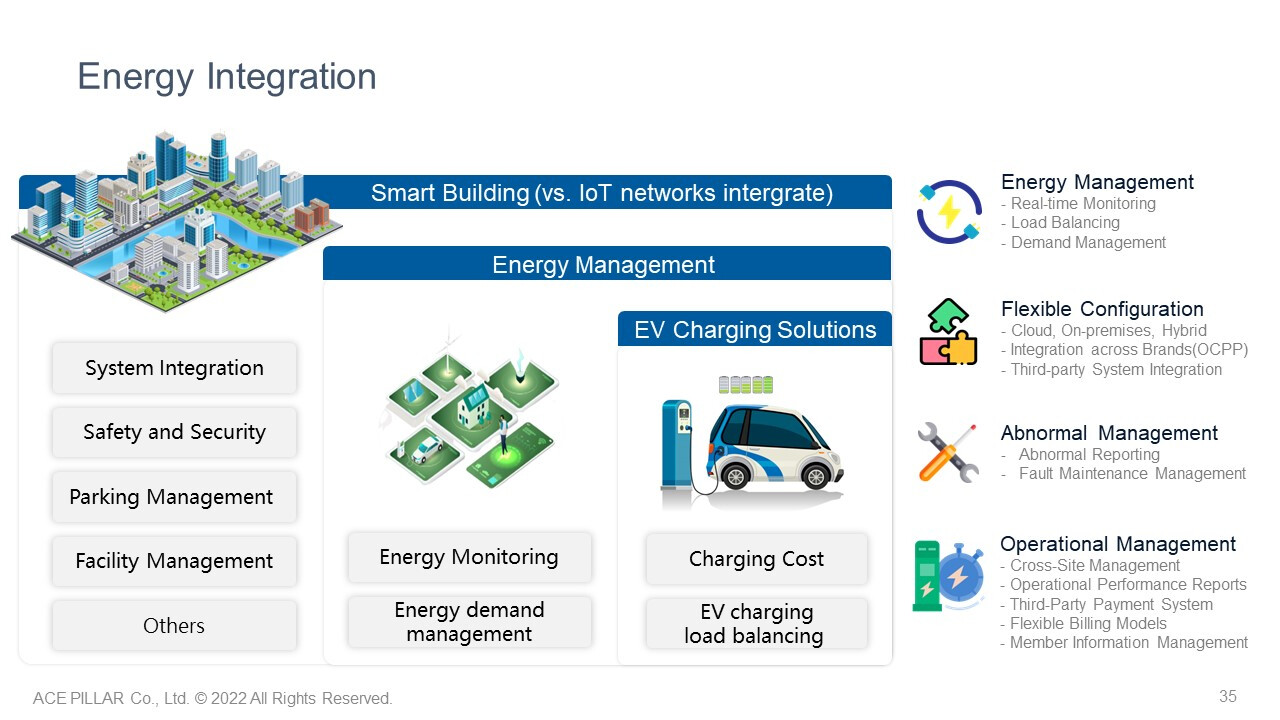

Charging billing, load balancing scheduling, demand control, system integration, and energy management are all examples of services.

It is important to consider not just present needs but also future scalability when selecting charging stations. With advancements in electric vehicle technology, higher-power charging stations may be introduced to allow for faster charging speeds. Scalability must be a primary focus during installation to ensure that utilization is not limited for the charging station's electricity management. Billing, and even manage additional energy in various other capacities. Make sure your choice is easily adaptable or extensible to meet potential future demands.

Model Recommendations

FAQ

Determine whether it is powered by a private or public electricity meter.

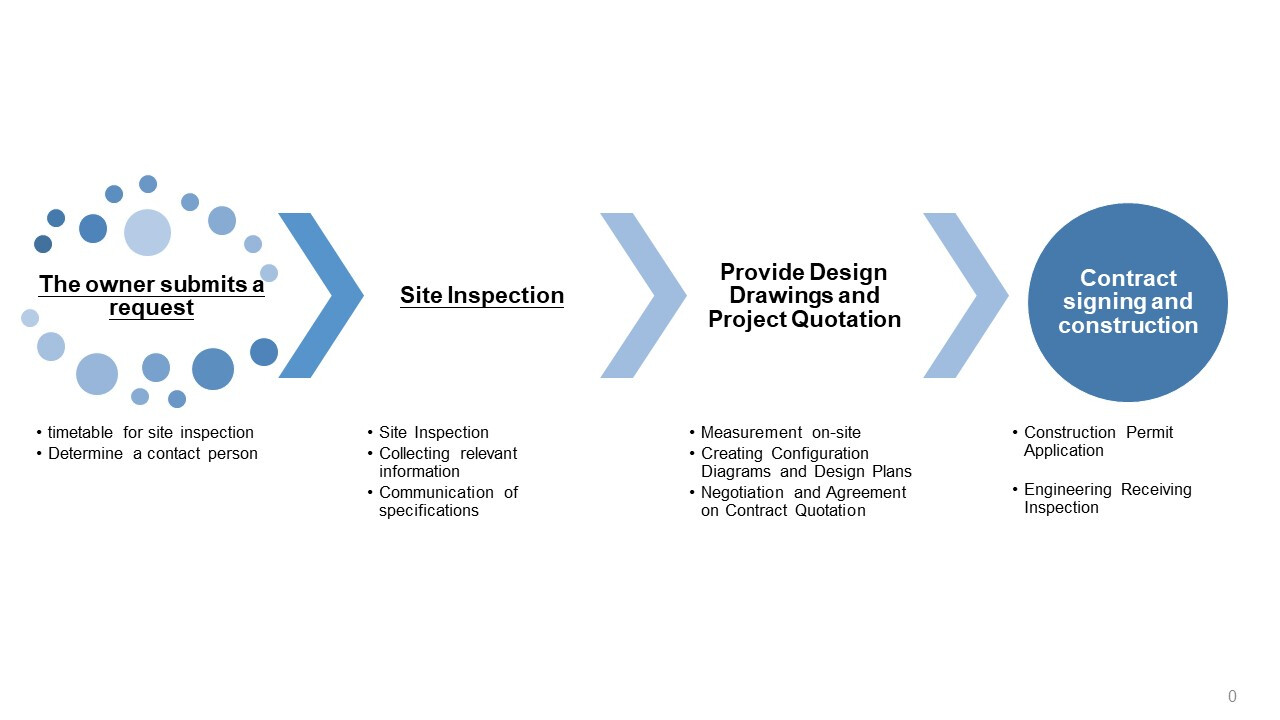

Installation Process

Safety First, Our Commitment

In addition to extensive testing and international safety certifications for the devices themselves, Ace Pillar goes above and above to ensure the quality of the entire charging system. We promise high-quality construction. It is performed by authorized specialists with government electrical installation licenses who inspect and plan the circuit before building and installing it. Furthermore, the EMS charging station may regulate charging power in real-time based on power supply status and charging demand at different locations, preventing wasteful power usage and power impacts. This not only decreases the burden on management personnel and staffing, but it also significantly reduces the likelihood of personnel operating blunders.

Success Stories

Related Product