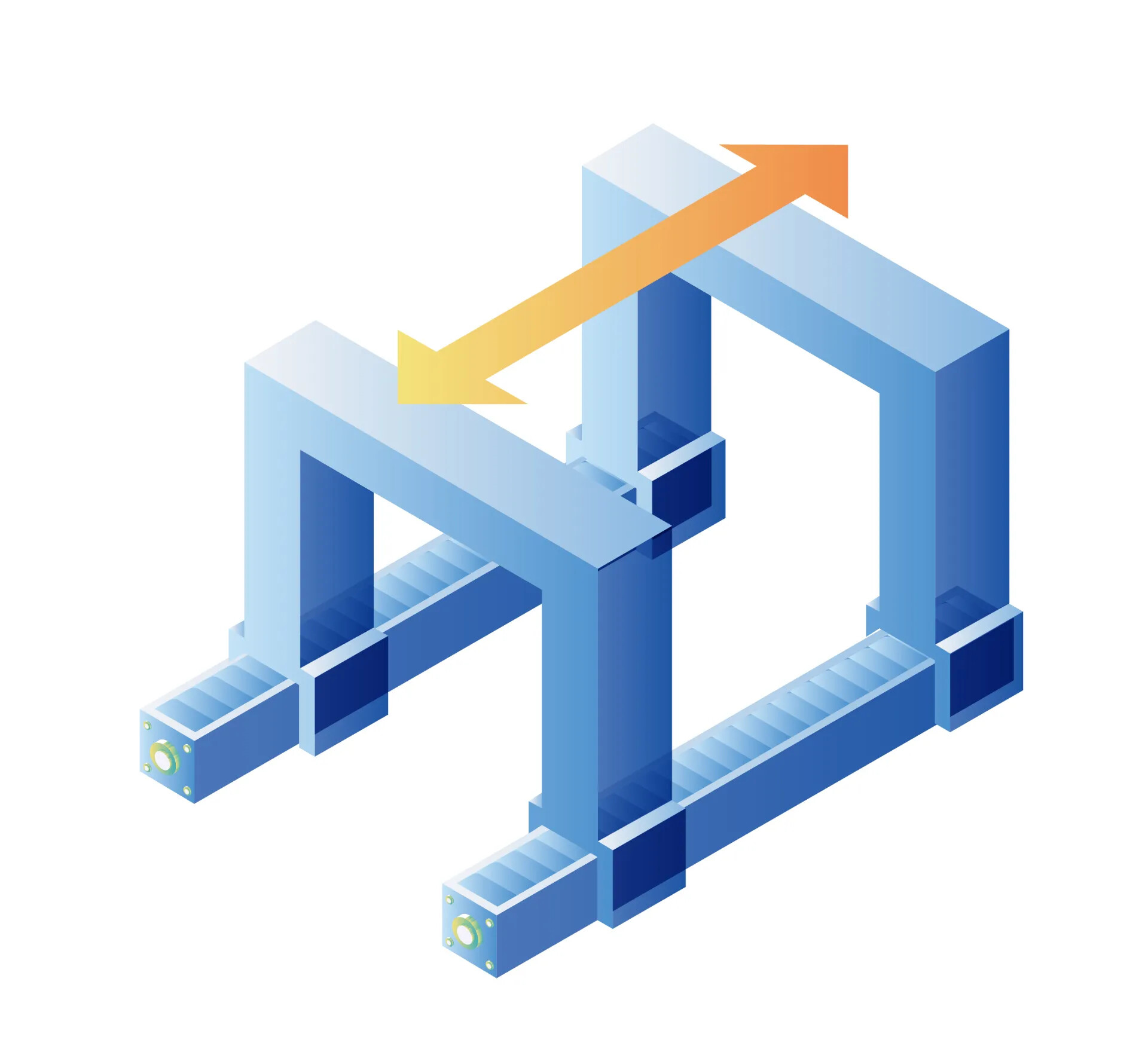

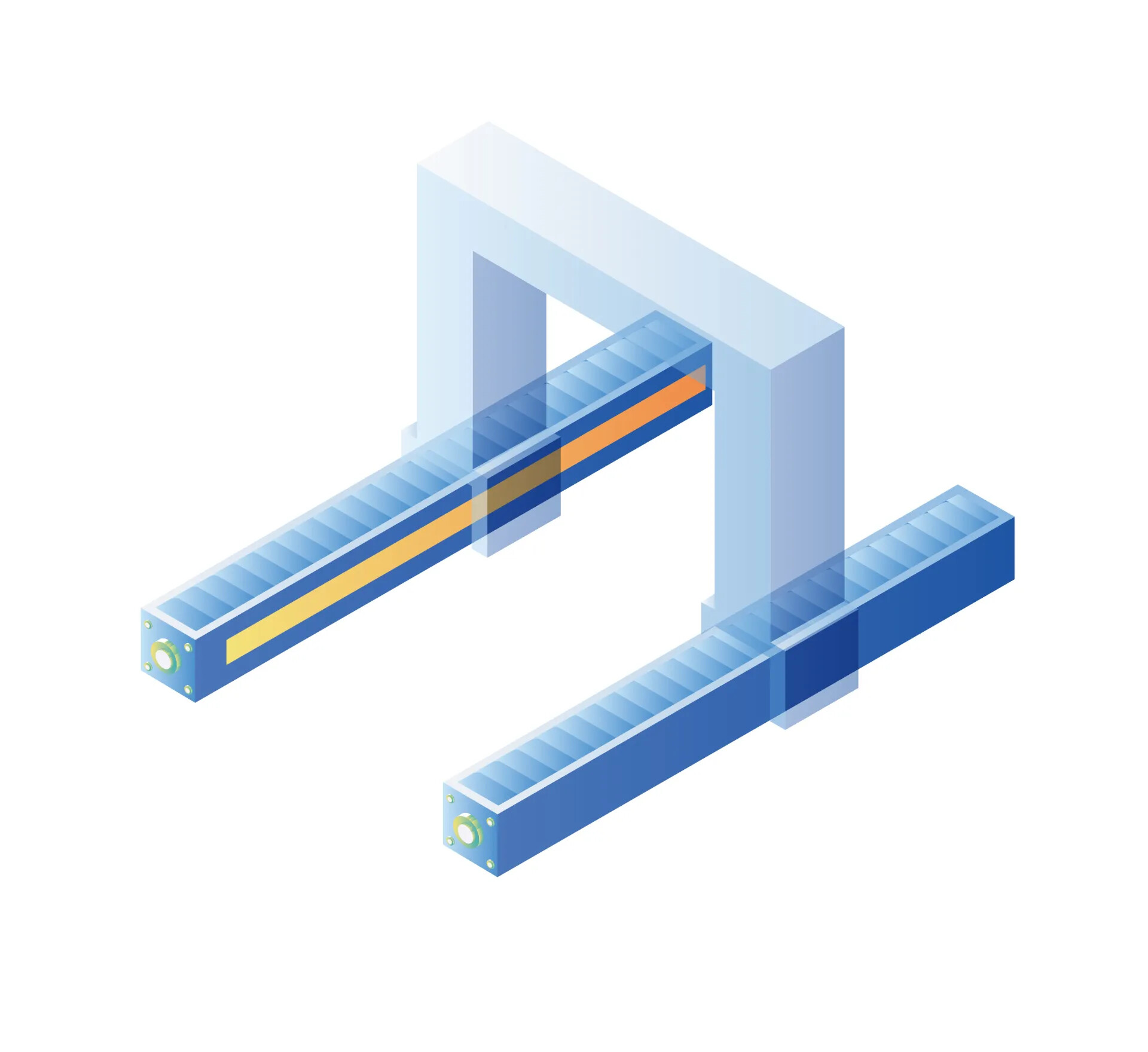

"In simple terms, it means controlling a motor on each shaft and allowing the two motors to move together, stop together, and jointly control the same mechanical shaft."

In today's industrial world, efficient and precise motion control is critical for many mechanical systems. To accommodate consumer requests or overcome limits imposed by workspace, processing procedures, or processed commodities, a structure like an arch has been created.

Gantry synchronization is used to control the consistent speed of two movable platforms. Maintaining synchronized movement between the two shafts is critical to preventing mechanism damage. As a result, achieving synchronized movement control between the two shafts is the primary concern in gantry synchronization.

When should Gantry Synchronization be used?

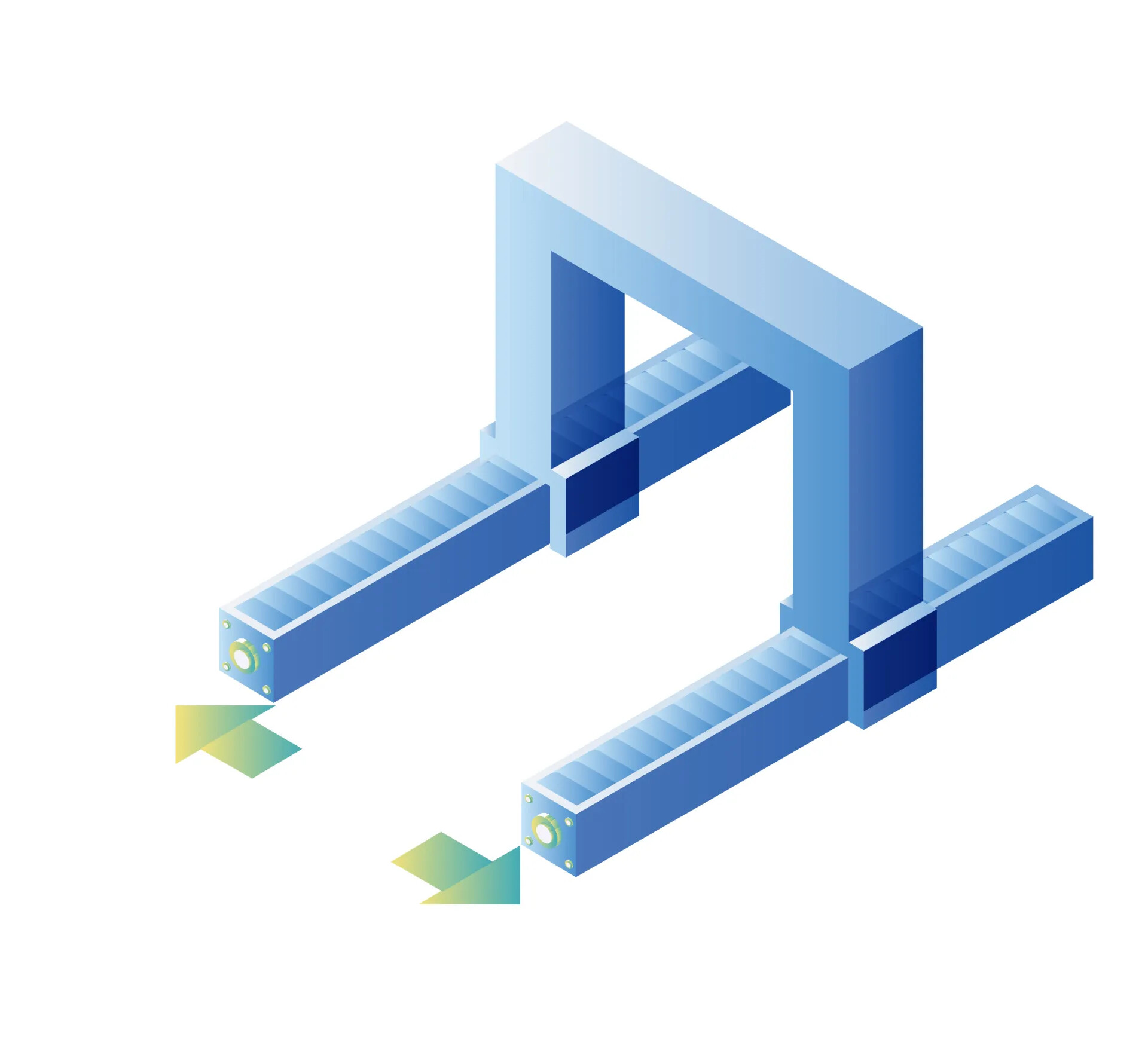

1. When the distance is too large and the mechanism does not allow for one-sided motoring, requiring both sides to move simultaneously.

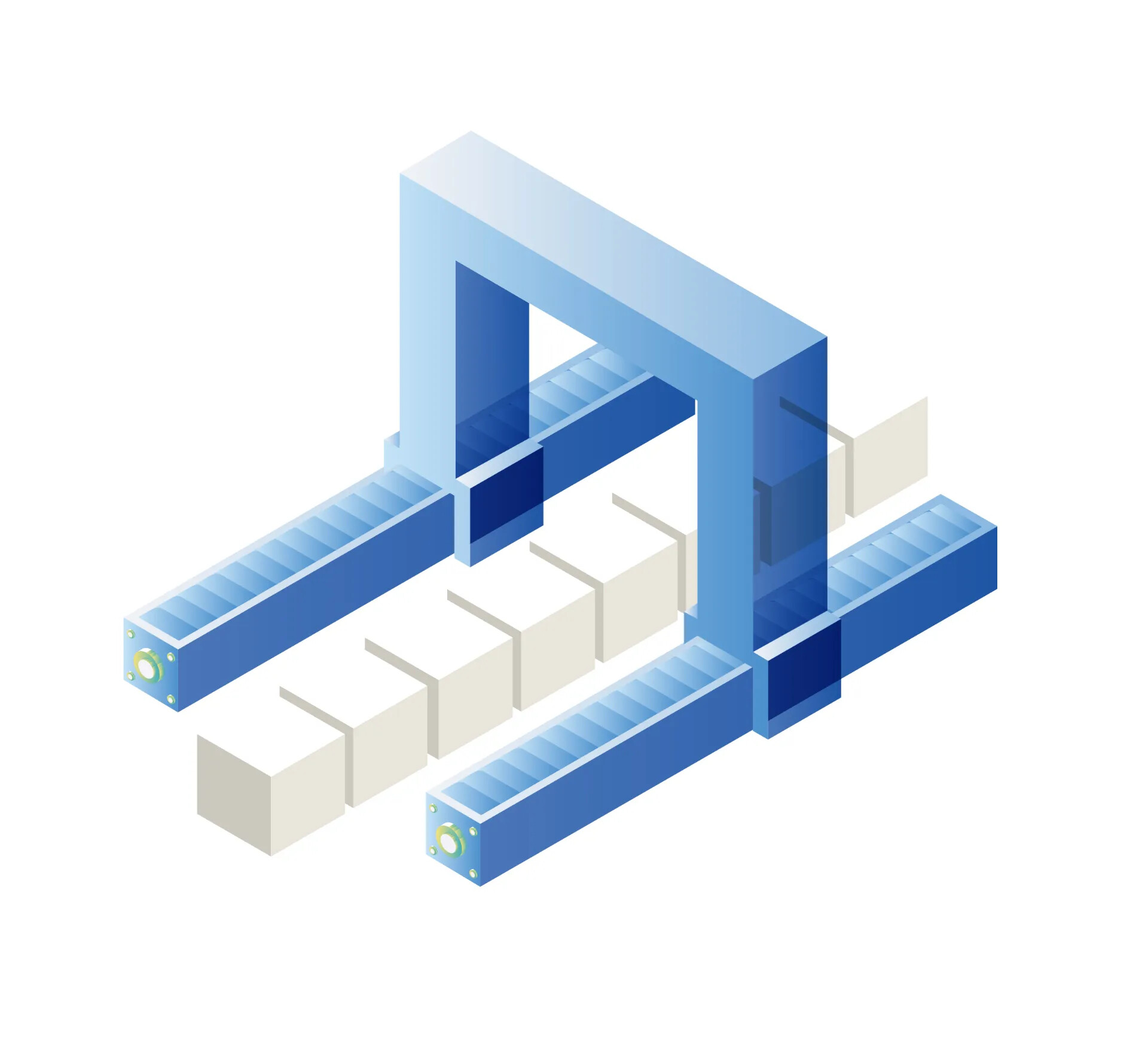

2. When dealing with a large number of objects that are placed in a matrix and are awaiting processing/inspection.

3.When a considerable working range is required in the center, but the mechanism does not allow for central drive and a motor cannot be installed separately in the central area.

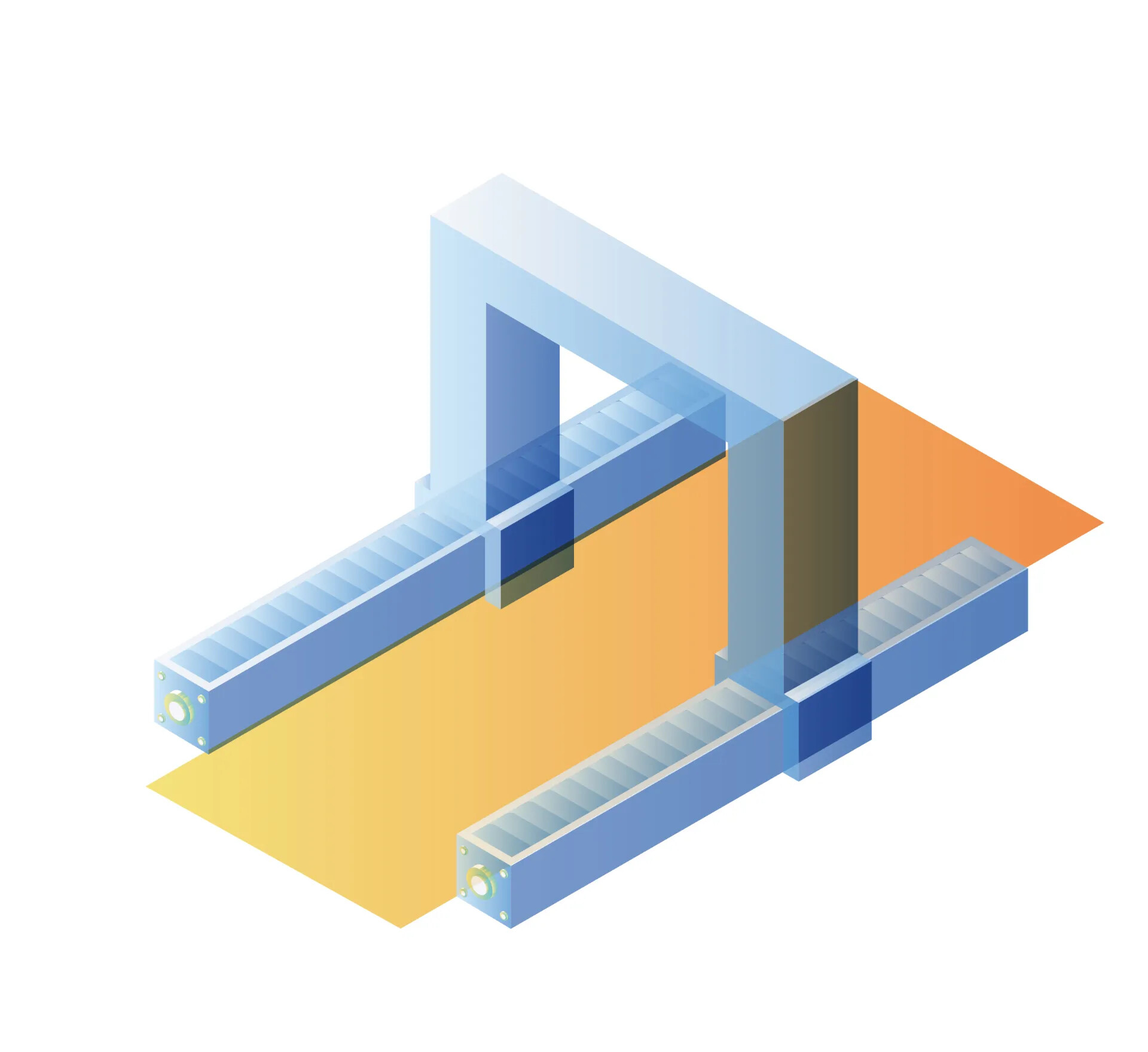

4. When high precision is required, optical rulers can be put on both sides of the machine to achieve greater motion control accuracy.

FAQ

The gantry structure, which is outfitted with Delta motor drivers, is capable of correcting deviations. When deviations occur on both sides of the mechanism owing to a power loss, a standstill, or other factors, Gantry Synchronization can quickly correct them, ensuring the continuous stable operation of the mechanical equipment.

Success Stories