SECS/GEM for Semiconductor Automation: Practical Integration in Modern Fabs

As semiconductor manufacturing continues to advance toward higher efficiency and intelligence, seamless data communication between equipment has become a critical challenge for improving productivity. However, the wide variety of communication protocols across different brands often leads to complex system integration, longer development cycles, and risks to delivery schedules and production stability.

In this environment, the SECS/GEM communication standard has emerged as the universal language of semiconductor automation.

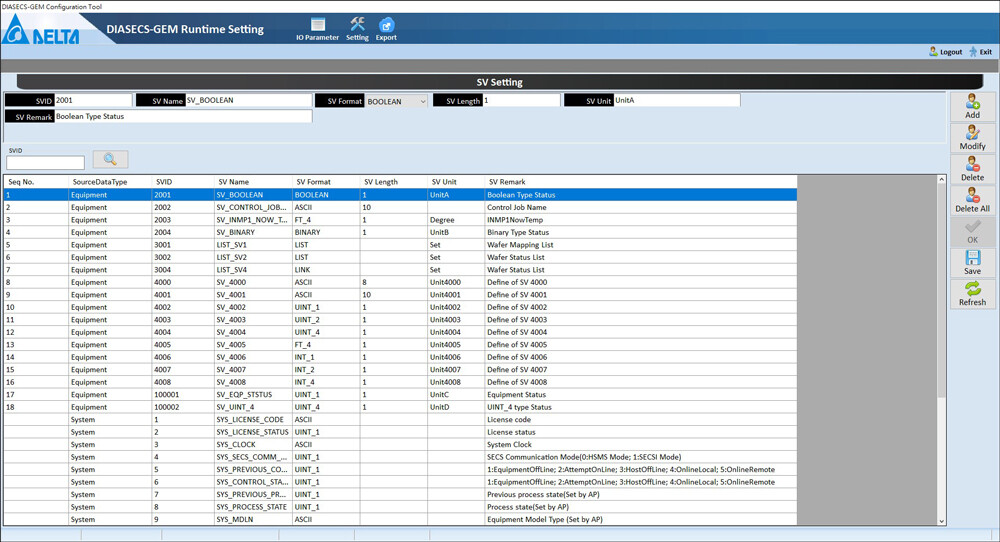

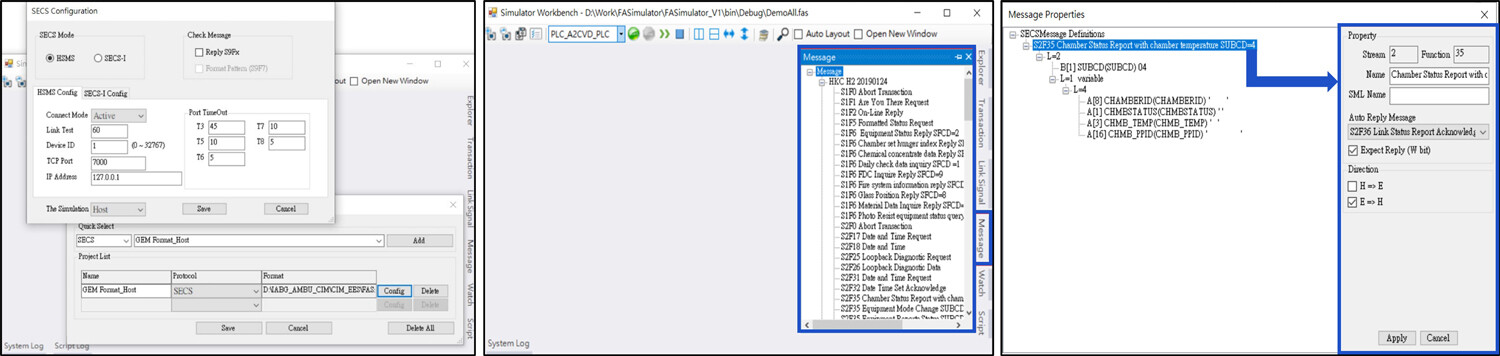

By integrating Delta’s DIASECS platform with industrial IPC through Luo Sheng’s expertise, equipment developers can replace traditional coding with configuration-based workflows, enabling rapid deployment of a stable and reliable communication architecture. This not only shortens development and integration time but also empowers production lines with real-time monitoring and smarter decision-making capabilities.