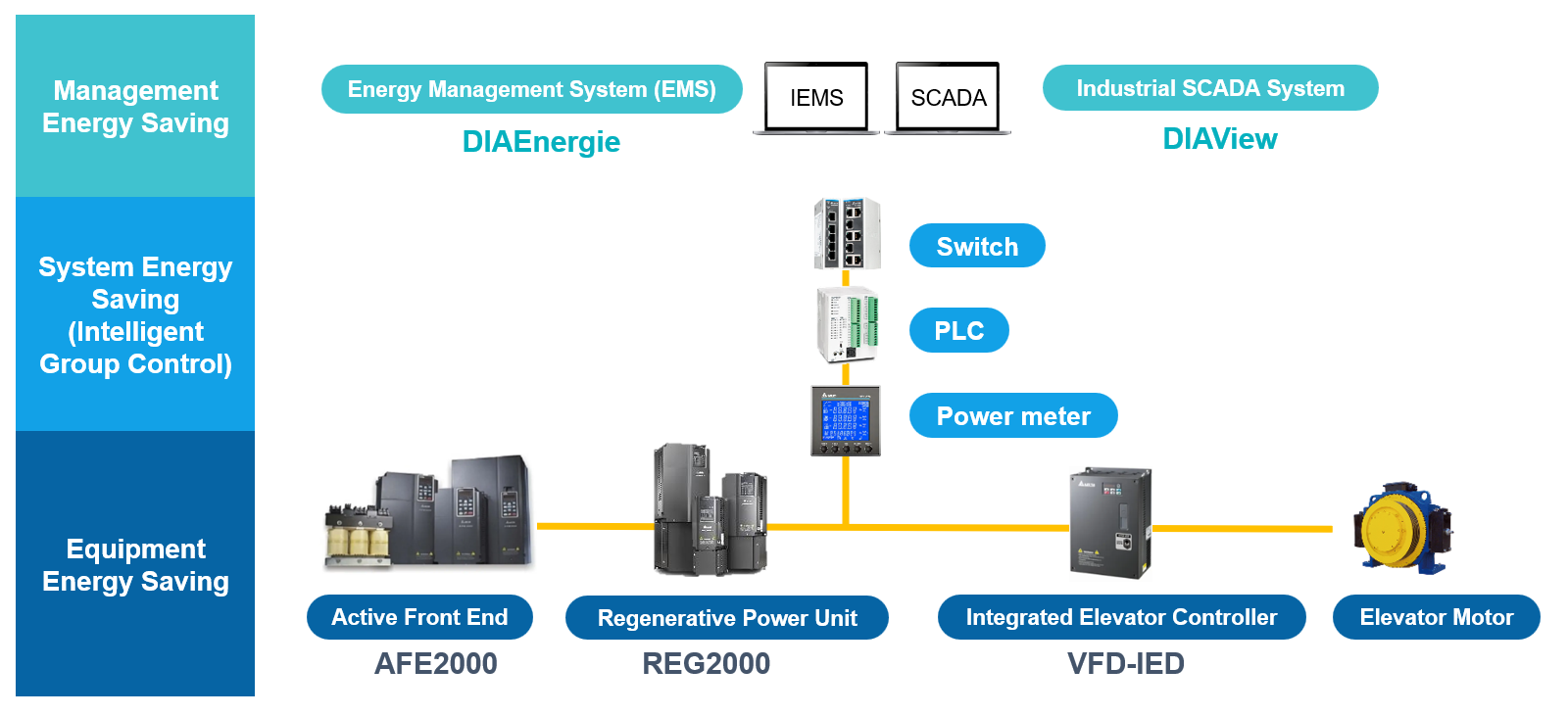

In today’s rapid growth of smart buildings and smart manufacturing, energy efficiency is no longer a “bonus”—it’s a necessity. Beyond HVAC, lighting, and power systems, there is a major category of energy consumption that is often overlooked: dynamic equipment with frequent start–stop cycles, acceleration and deceleration, and bidirectional load movement.

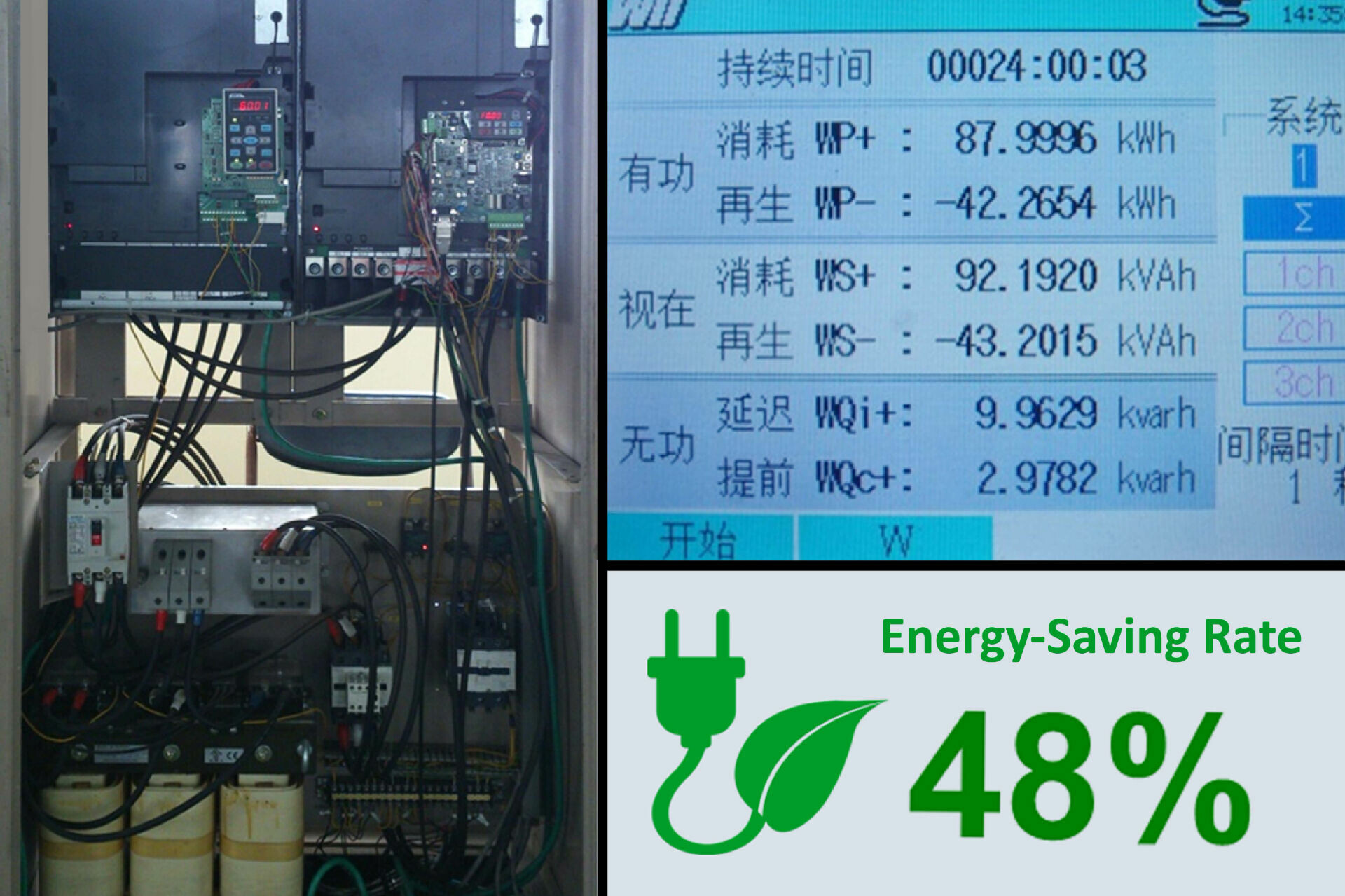

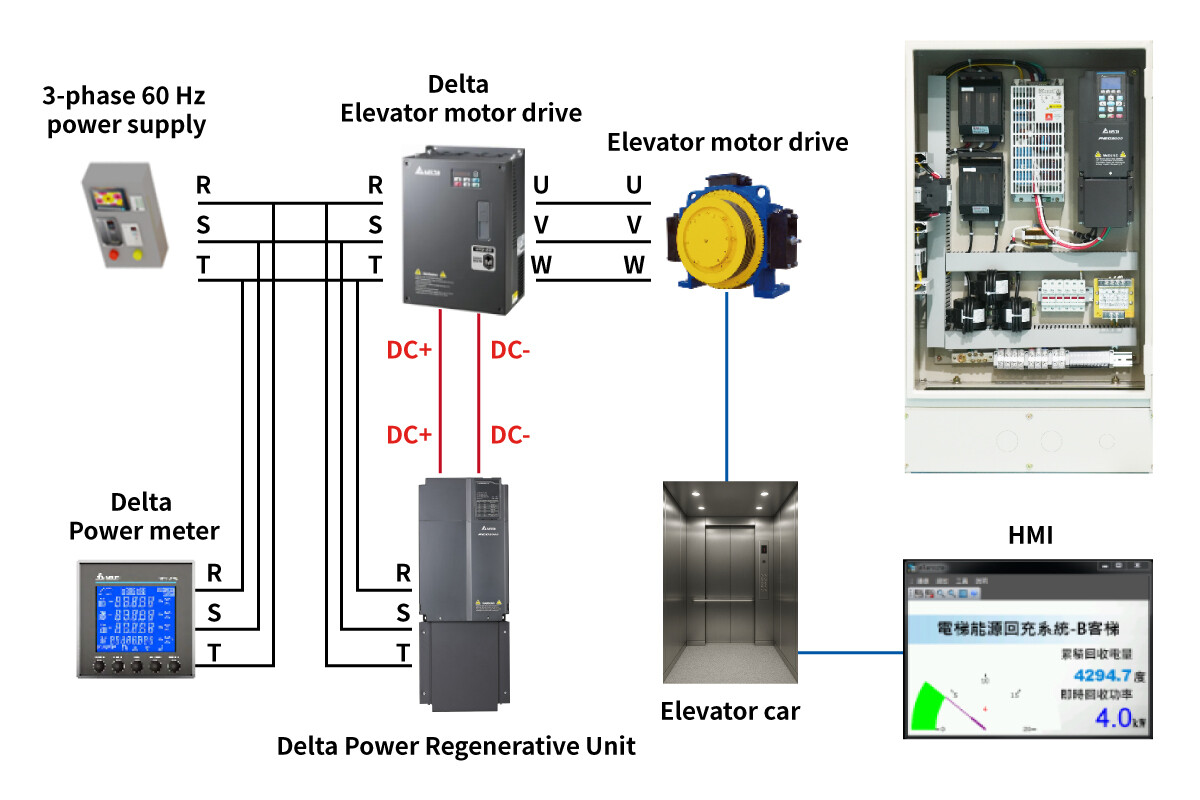

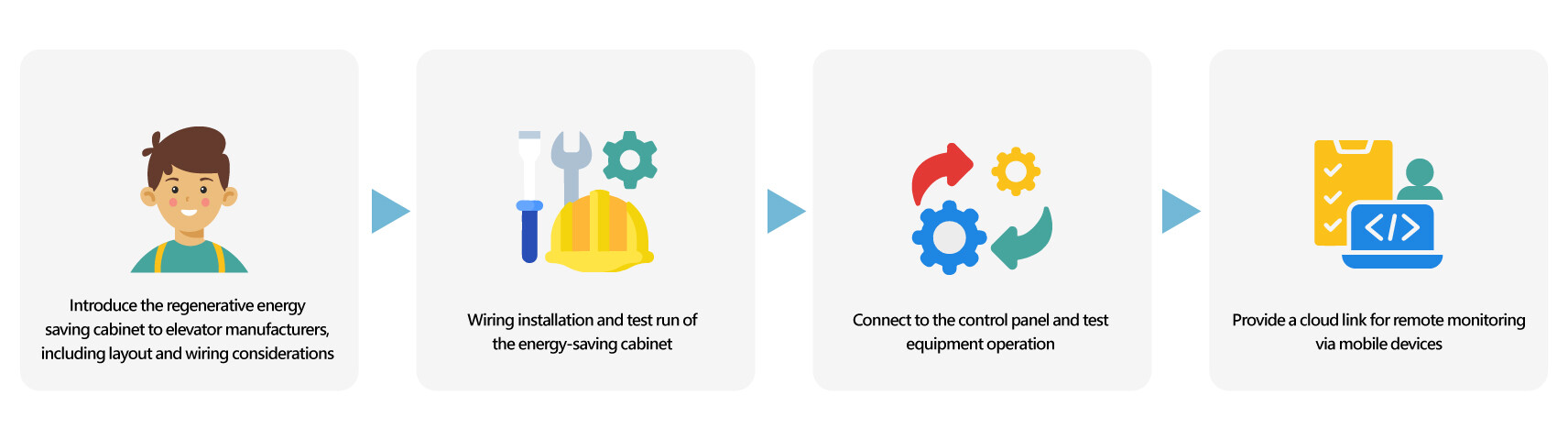

The core value of the regenerative power saving cabinet lies in recovering and reusing the energy that would otherwise be wasted during braking or load changes, effectively elevating the overall energy efficiency of a building or production line. This is not only about reducing electricity costs—it’s a crucial step toward low-carbon operations, ESG goals, and long-term sustainability.