In the fields of semiconductor OSAT (Outsourced Semiconductor Assembly and Test) and wafer foundries, the packaging efficiency and stability of IC trays directly impact throughput at the shipping stage. From end-of-line collection and sorting to final outbound packaging, any disconnect in the process flow can create bottlenecks that delay overall lead times.

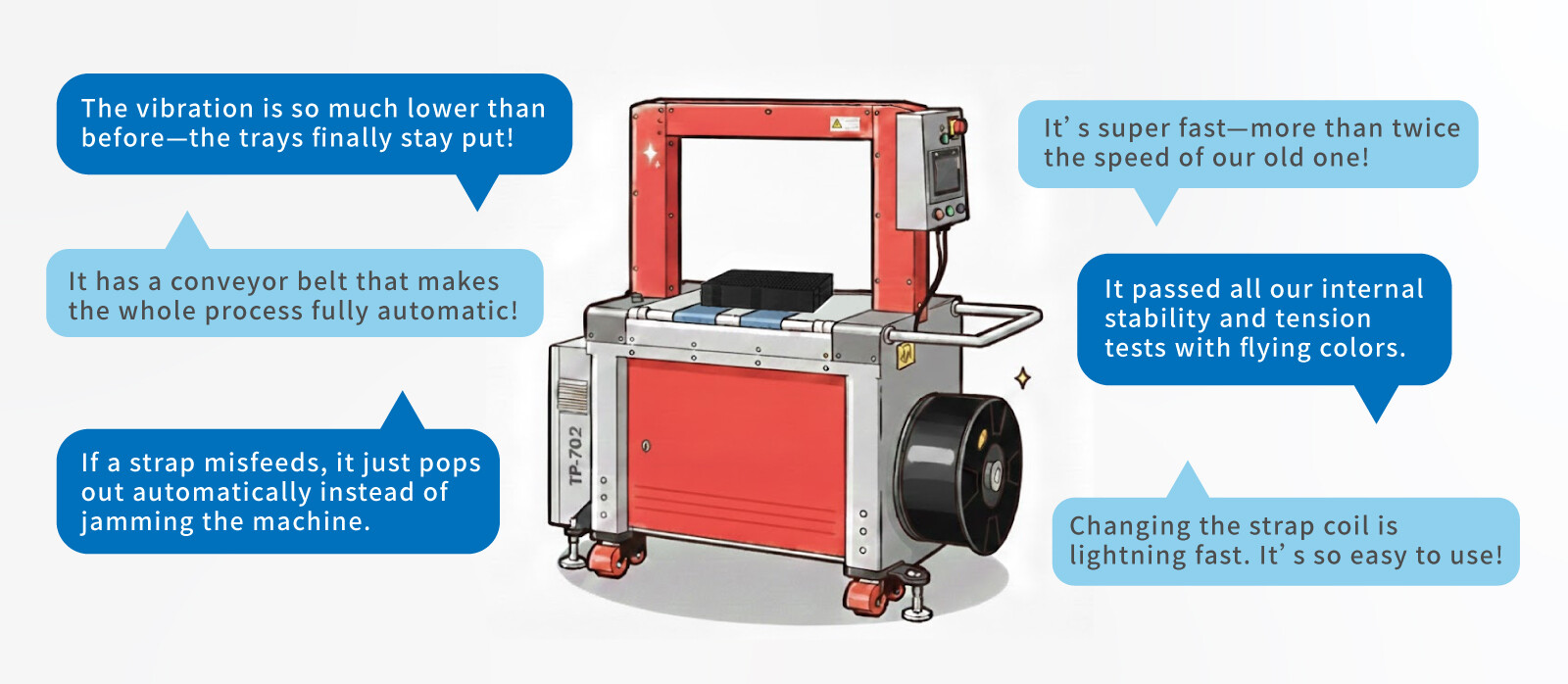

However, most facilities still rely heavily on manual labor for tray sorting and handling. This not only incurs high labor costs but also leads to issues such as unstable stacking, tilting, or jamming due to operator fatigue or inconsistent handling. Furthermore, legacy equipment often lacks the necessary precision and stability, resulting in frequent unplanned downtime after prolonged operation. These factors diminish production line utilization (OEE) and have become critical pain points in high-tact-time manufacturing environments.