"We struggled with randomly placed parts in our storage bins. We approached many companies for evaluations, only to be told 'it can't be done.' Thankfully, Ace Pillar stepped in, quickly assessed the situation, and delivered a solution. It’s been in operation for some time now, and the stability is impressive." — Mr. Chen, Facilities Manager, Taichung Metalworking Plant.

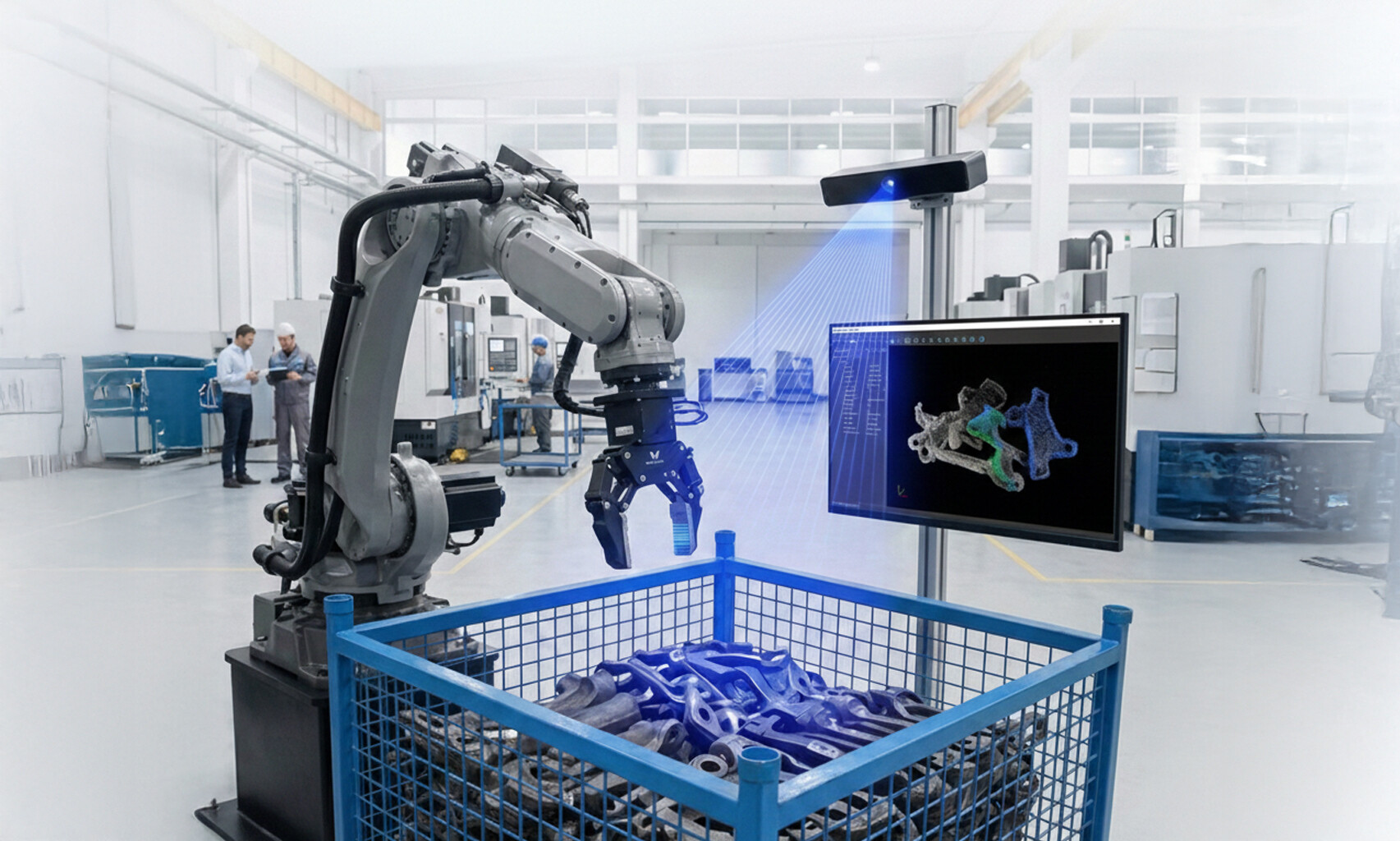

AI-Powered 3D Vision: Solving Random Bin Picking in Metalworking

Case Study: Taichung Precision Metal Processing Factory

"In Taiwan, metal processing and automotive parts manufacturing are vital links in the global supply chain. However, relying on manual labor to pick parts from wire mesh containers and load them into machines for processing poses significant challenges. With individual parts weighing between 5 to 20 kg, the physical strain on workers is immense. Beyond the issues of high repetition and low efficiency, the industry has been severely impacted by acute labor shortages in recent years."

Industry Pain Points | Pain Points of Conventional Solutions |

|---|---|

Difficulties in | Conventional vision lacks spatial depth (Z-axis) data, which hinders its ability to identify 3D poses or handle height-based occlusions. This makes it impossible to achieve efficient and precise pick-and-place operations for randomly layered components. |

Challenges of Metallic | High surface reflectivity and oil stains on parts create significant interference for conventional vision systems. |

Requirements for | High-Precision Assembly Barriers: Critical high-precision machined components (such as automotive suspension parts) require an assembly placement accuracy of 50μm (microns). Such precision is difficult for manual labor to maintain consistently over time, which adversely affects overall product yield. Consequently, parts must be fed into machine tool fixtures or positioning jigs with high stability and precision to ensure the reliability of subsequent precision machining processes. |

High-Mix, Low-Volume (HMLV) | The system offers high flexibility for line changeovers, enabling rapid responses to market changes. |

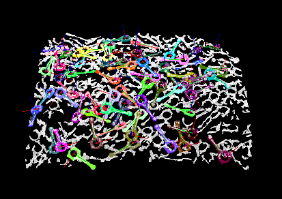

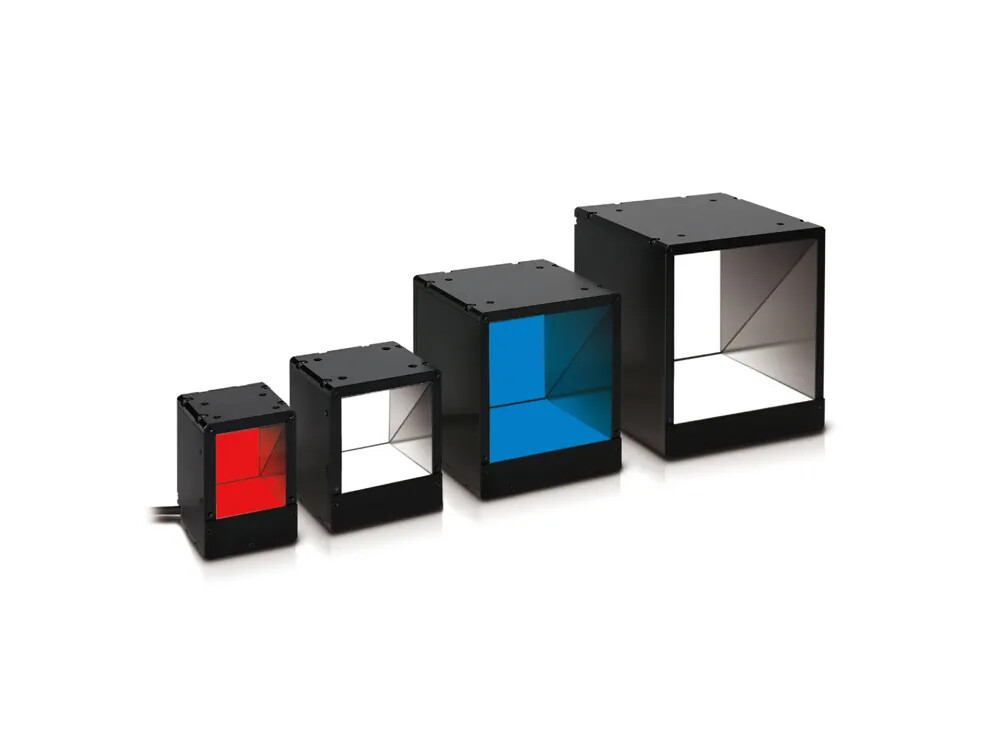

Compared to traditional models, point cloud loss and flying pixels in dark and highlighted areas are reduced by 90%.

Redefining Vision: 3D Automation Solutions by ACE PILLAR

Our automation solutions are engineered for the toughest metal processing challenges: heavy loads and disorganized materials. Leveraging cutting-edge 3D vision and AI-driven guidance, we bridge the gap between advanced intelligence and robust heavy-duty handling.

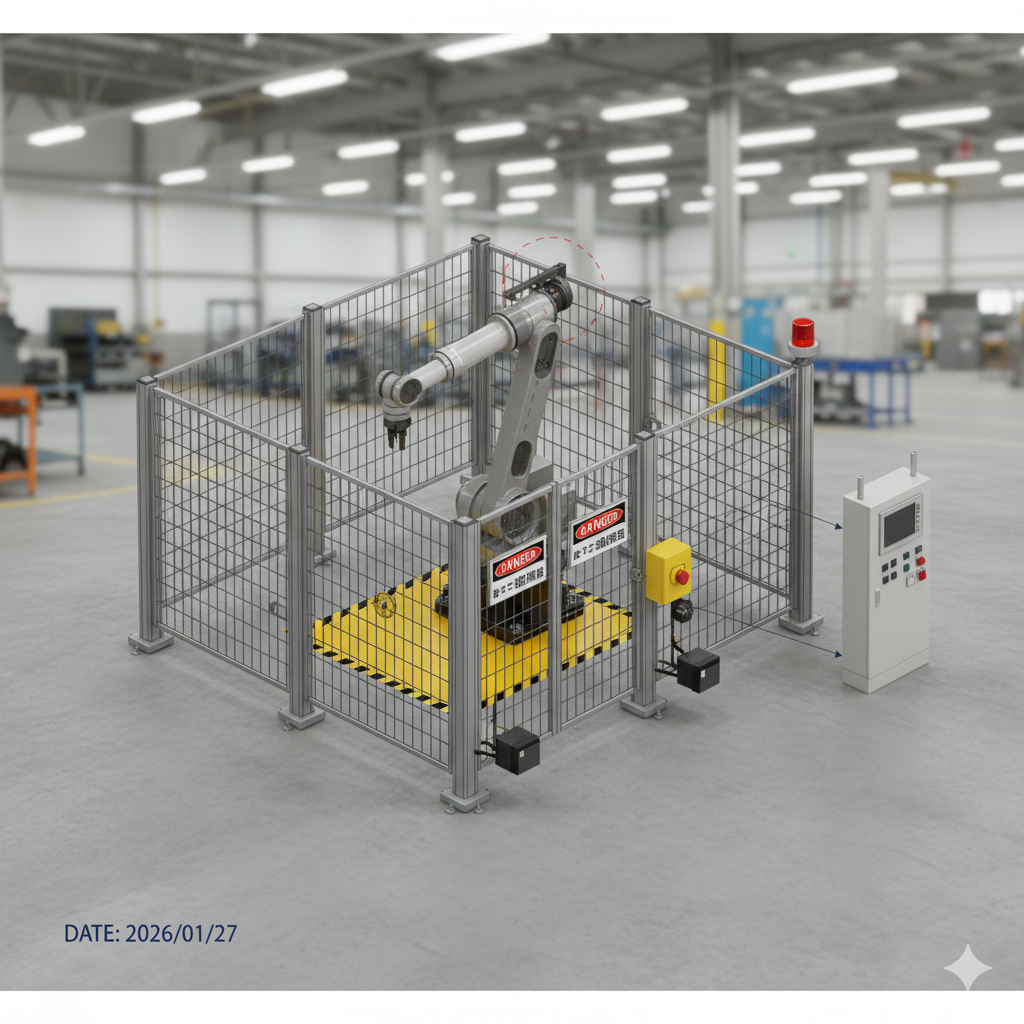

ACE PILLAR Integrated Service Process

Application Workflow

Technical Modules | Demonstrating Professional Advantages |

|---|---|

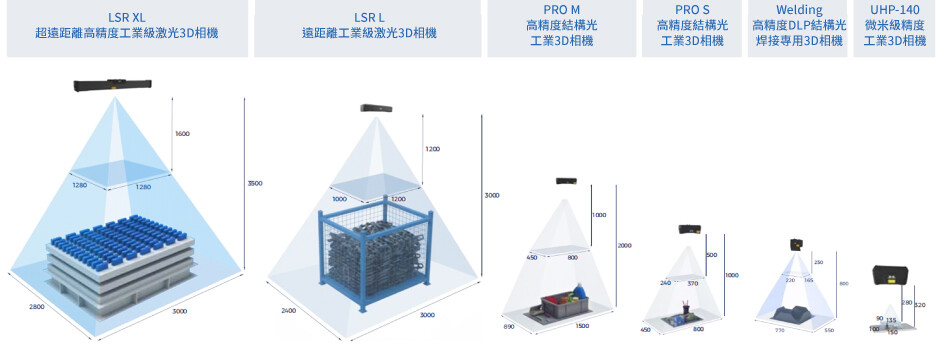

High-Resolution 3D Sensing Hardware | Utilizing industrial-grade 3D cameras combined with proprietary structured light technology and anti-reflective filtering, the system outputs ultra-high-quality, low-noise point cloud data even in harsh environments. |

AI & Deep Learning Core Algorithms | Powered by an AI deep learning platform, the system excels at analyzing parts in randomized piles. The model training quickly adapts to complex occlusions and overlapping, maintaining a stable pick success rate of over 95%. |

Intelligent Path & Collision Planning Software | With a built-in intelligent motion planning engine, the system automatically generates optimal collision-free picking paths based on part orientation, gripper models, and bin boundaries. For heavy-duty parts, it automatically adjusts the robot’s velocity curves to ensure maximum safety and stability during handling. |

Rapid System Deployment & Maintenance | Featuring a zero-code graphical interface, engineers can quickly import new CAD models and complete changeovers via software. This significantly reduces deployment and maintenance costs while enhancing system deployment speed, maintenance convenience, and overall production flexibility. |

Proven Results and Data: Return on Investment (ROI) Exceeds Expectations

This solution has been successfully implemented in automotive critical component production lines, achieving significant productivity gains and resource optimization results:

KPIs | Key Benefits & Local Value |

|---|---|

Feeding Efficiency | Daily output increased from 200 to 450 units, representing a 125% boost in production efficiency. Throughput is now stable and predictable. |

Feeding Stability | Ensures reliable material positioning with minimal deviation, significantly reducing machine downtime caused by unstable feeding into fixtures. Yield rates have steadily improved by 18%, meeting international supplier quality standards. |

Labor Savings | Effectively eliminates occupational injury risks associated with heavy lifting and solves the critical frontline labor shortage. |

Return on Investment (ROI) | The estimated Payback Period is within 14 months, delivering a rapid return on investment. |

System Flexibility | Achieves high production agility with rapid new model configuration, supporting quick switching between multiple part types to meet High-Mix, Low-Volume (HMLV) order demands. |

Call to Action: Your Tailored Solution for

"Unmanned Production" and "Efficiency Upgrades

Are you facing challenges such as occupational injury risks from heavy-duty parts handling or

low efficiency caused by unorganized material feeding?

Is your factory still assigning high-value talent to high-risk, low-efficiency tasks like heavy lifting and manual material sorting?

At ACE PILLAR, we are deeply rooted in Taiwan’s manufacturing industry and truly understand your pain points. Our 3D vision solutions are more than just technology—they are the key to securing your supply chain and enhancing your international competitiveness.

Contact our technical service team today to schedule a free feasibility study and ROI analysis.

We offer

Professional evaluations,

Site surveys, and Planning.

RECOMMENDED