Challenges in Strapping Large Cargo:

Professional Strapping Solutions to Flexibly Meet Diverse Needs

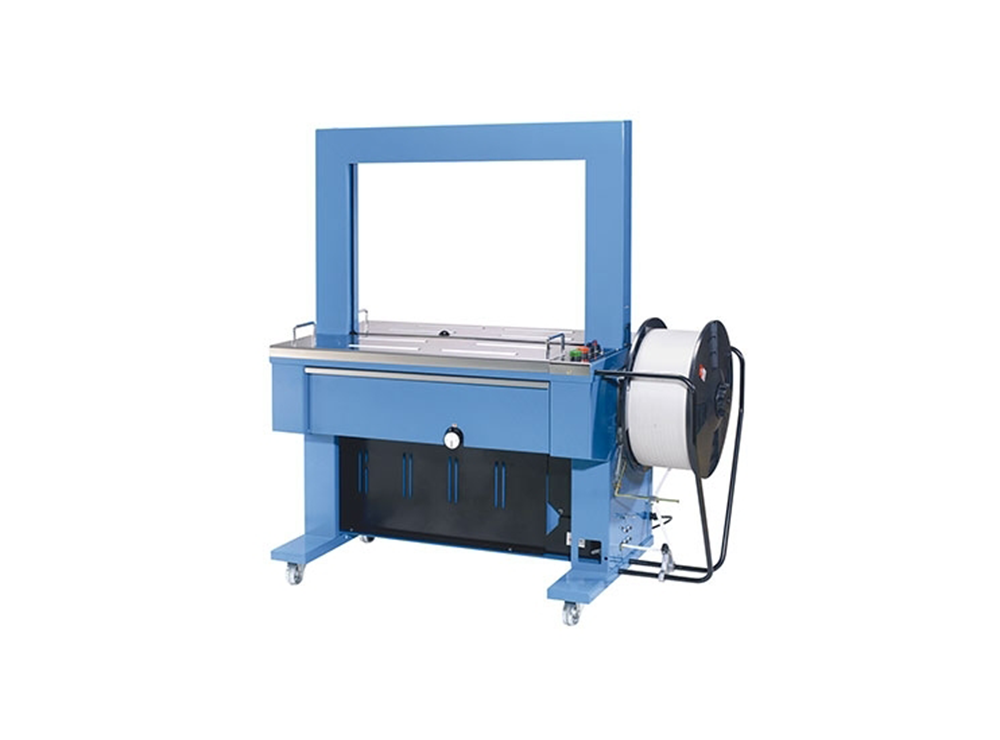

In logistics and manufacturing, packaging needs vary across different scales, requiring tailored equipment support. Some businesses rely on handheld strapping machines to handle individual large shipments, while others seek to upgrade from semi-automatic strapping machines to fully automated systems due to efficiency limitations. Below are solutions for these two scenarios, designed to help businesses enhance both efficiency and stability.