- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

HES Series

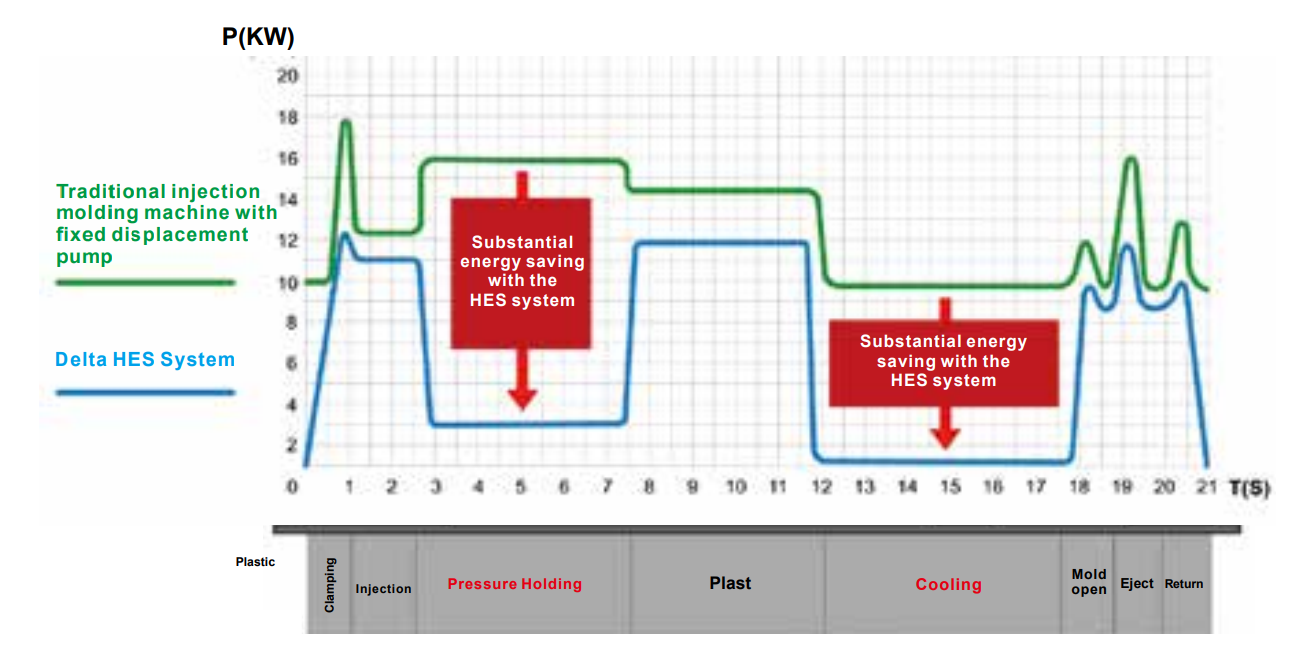

Delta's Hybrid Energy Saving (HES) System provides precise pressure and flow controls for each injection molding process and also solves the energy waste issues of a traditional injection molding machine. This solution helps to improve product quality, market competitiveness and productivity.

Ultra Energy-Saving

Saves up to 75% power consumption depending on the different injection conditions

Energy Consumption Curve of the Injection Molding Process

System Features

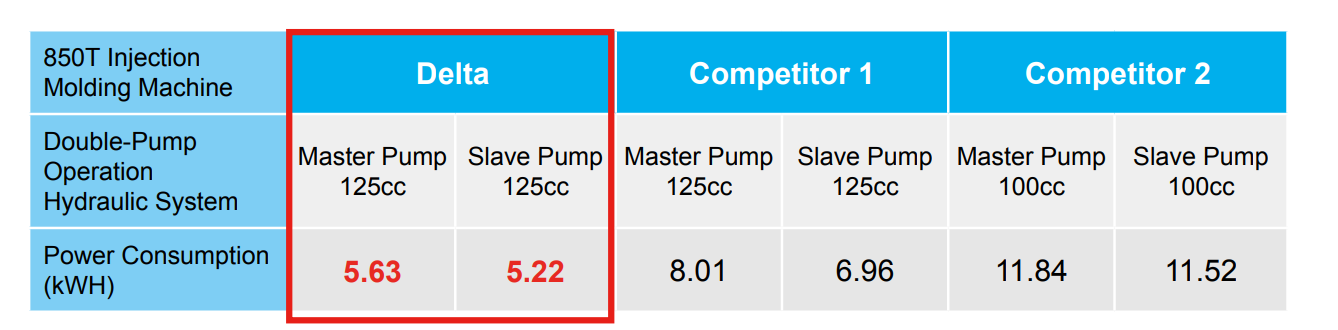

(1) Significant Energy Reduction

- A field test with an 850-ton injection molding machine adopted the Delta HES250M43 double-pump confluence hydraulic system.

- The Delta HES-C Series saved up to 109,500 kWh in energy consumption and reduced 69,861 kg CO2e emissions in a year compared with competing products operating 24 hours per day.

(2) Excellent Overload Capability

- All HES-C models feature overload capability of max. pressure 175bar for 60 seconds, and some of the advanced models can reach max. 8 minutes. All these models are especially suitable for thick products production. Please refer to the Pressure-Flow Characteristic Chart on the following pages for more details.

(3) Cost-Effective System

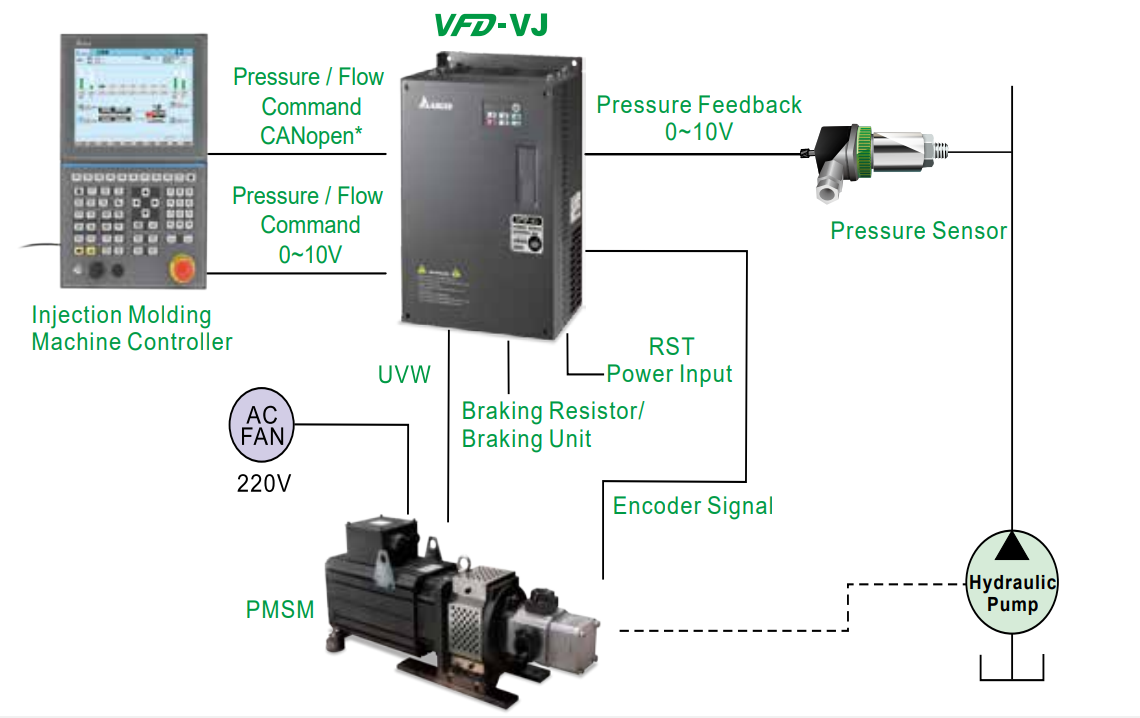

- Delta Hybrid Energy Saving System HES-C adopts Hybrid Servo Drive VFD-VJ Series and Fan Cooling

- Servo Motor MSJ Series, and features high torque and low inertia. This allows users to select the Hybrid Servo Drive VFD-VJ Series and Servo motor MSJ Series with lower power ratings to save system cost.

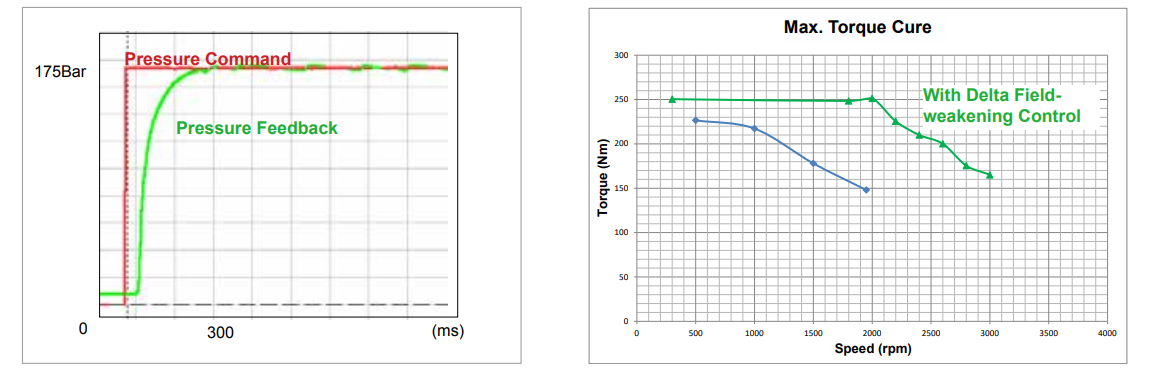

(4) PID Pressure Control

- Using Delta's special PID control technique, the system is able to perform pressure overshoot under 3 bar with optimized response time and stable product weight.

(5) Field-Weakening Control of a Motor

- Delta's servo drive uses motor field-weakening control to effectively extend the motor operation

- scope, increase system flow and ensure productivity of the injection molding machine.

(6) Easy Commissioning

- Users can directly use the Delta preset motor and hydraulic system parameters without the need for additional tuning.

- Simply install the drive to easily begin the operation.

(7) Excellent Performance

- Short response time enhances response speed of the system

- Great V/P transfer capability elevates product yield rate

- Lower noise compared with traditional dosing pump

- Stable oil temperature rise

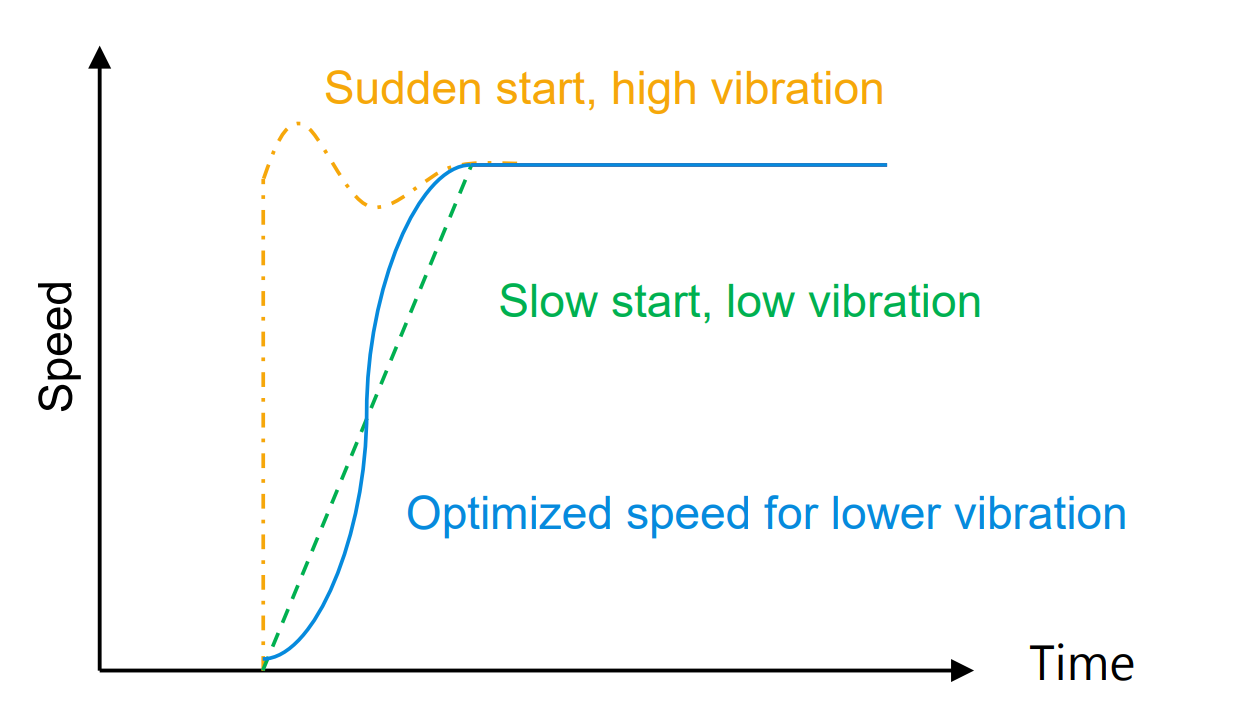

(8) S-Curve Control

- Smooth operation reduces machine vibration

(8) S-Curve Control

- Smooth operation reduces machine vibration

(9) Multiple Protections

- Multiple protection functions, including over current, over/low voltage, over heating, brake protection,

- insufficient pump oil protection. Complete protection prevents the equipment from anomalies and

- serious malfunction, and enhances system lifetime.

- Real-time monitoring of the motor temperature is via a KTY84-130 temperature sensor embedded in the motor winding.

(10) Multiple Pumps Control

- Capable of controlling up to 12 pumps and multiple master/slave pumps system architecture. Users can integrate systems with a different HES-C flow rate depending upon the system requirements of the machines.

(11) User-Friendly Software

- User-friendly software for machine commissioning.

- The software presents real-time system parameters such as pressure, flow, motor current and motor speed.

(12) System Monitoring and Controller Integration

- Built-in PG and communication card, and USB port to connect industrial 3G routers for system monitoring and software upgrade.

- Supports CANopen communication protol, enhancing integration with the controllers

System Structure

Download

- Solution

- Products

- Brand

- Support

- Sustainability Strategy

- Foreword

- Corporate Governance Operation

- Business Partnership

- Create Shared Value

- Sustainable Environment

- ESG Report

- Stakeholder Questionnaire

- How to Buy

- About

- Support

- Others

- ACE PILLAR Subsidiary Website